Call us today!

Blog

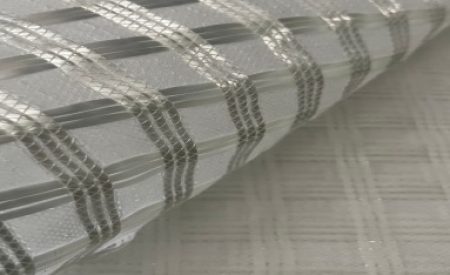

What’s Polyester(PET) Geogrid ?

Lianyi®Polyester(PET) Geogrid is biaxial geogrid made of high tensile strength polyester yarns coated by bitumen or PVC.PET Geogrid has high tensile strength which is resistant to damage,corrosion and has long term durability.

Features Of Polyester(PET) Geogrid

*Reduces the thickness of embankment material

*Accelerate the construction period

*Provides long term durability

*Provides optimal construction system quality

Advantages Of Polyester(PET) Geogrid

*Reduces and even eliminates the need to replace of soft bottom soil

*Reduces the volume of embankment material significantly

*Increase the quality of soil compaction and more uniform

*Able to control and minimize differential settlement

*Distribute of the soil pressure evenly

Applications Of Polyester(PET) Geogrid

*Highway

*Railway

*Soil improvement, soft soil improvement on access road areas,manufactures,airports,mining areas

*Reclamation area

*Slope reinforcement

*Retaining wall

Keywords:

1.Polyester Geogrid

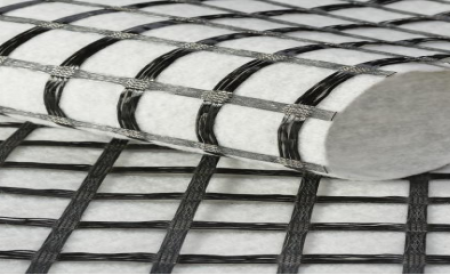

What’s Polyester(PET) Geocomposite ?

Lianyi®Polyester(PET) Geocomposite is a needle punched non woven geotextile reinforced by high tenacity polyester yarn.This reinforcing yarn is knitted with the non woven geotextile to make a high tensile strength geotextile with a good drainage property.

Features Of Polyester(PET) Geocomposite

*Reinforcement inserted with special webbing on non woven to make one composite geotextile *High permeability, friction angle, and high tensile strength at low strain

*Environmentally friendly(non-toxic) and resistant to chemical material

*Efficient, cheap and fast installation

*Serves to strengthen and stabilize the soil,while enhancing CBR surfaces

*Avoids cracked surface due to effects of differential settlement while avoiding loss material due to intermixing with soft soil

Advantages Of Polyester(PET) Geocomposite

*Reduces and even eliminates the need to replace of soft bottom soil

*Reduces the volume of embankment material significantly

*Increase the quality of soil compaction and more uniform

*Able to control and minimize differential settlement

*Distribute of the soil pressure evenly

Applications Of Polyester(PET) Geocomposite

*Reinforcement of highway foundation, an embankment on soft soil and swamp,etc

*Retaining wall

*Strengthening slope of embankment

What’s Glass Fiber Composite Grid ?

Lianyi® Glass Fiber Composite Grid Pavement Reinforcement System and Moisture Barrier System is manufactured at Feicheng LianyiEngieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.Glass Fiber Composite Grid is a composite material consisting of fiberglass reinforcement grid coated in an elastomeric polymer, bonded to a non woven paving geotextile. The non woven geotextile is a staple fiber, needle punched and manufactured from fibers that are needled to form a stable network and retain dimensional stability relative to each other.Glass Fiber Composite Grid is resistant to ultraviolet degradation and to biological and chemical environments normally found in soils.

Features Of Glass Fiber Composite Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Low elongation

*Thermal and chemical stability

Benefits Of Glass Fiber Composite Grid

*Universal application on milled surface or over existing pavement surfaces

*Quick and efficient installation

*Efficient moisture barrier due to the non-woven fabrics

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Glass Fiber Compsoite Grid

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

1.Asphalt Fiberglass Geogrid

2.Fiberglass Geogrid

3.Self- Adhesive Fiberglass Geogrid

4.Fiberglass Geocomposite

5.Fiberglass Geogrid Composite With Nonwoven Geotextile

6.Fiberglass Geogrid Stitched With Nonwoven Geotextile

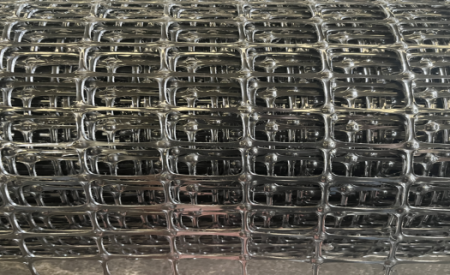

What’s PP Biaxial Geogrid ?

Lianyi® PP Biaxial Geogrid is biaxial geogrid made of PP(polypropylene)material and is available with strengths of up to 60kN/m. PP Biaxial Geogrid is used as a solution for the problem of road embankment,embankments on soft soils,slope reinforcement structures,and so on. PP Biaxial Geogrid can improve sub grade and sub-base performance by acting as a reinforcement for the embankment material.PP Biaxial Geogrid becomes more effective when the projects have to deal with some geotechnical complexity. This material provides road pavement strengthening through high tensile strength and excellent interlocking capability.

Features Of PP Biaxial Geogrid

*Reduces the thickness of embankment material

*Simplifies the construction process

*Extends the life of the road service

*Reduces the frequency of road repair

Advantages Of PP Biaxial Geogrid

*Reduces and even eliminates the need to replace of soft bottom soil

*Reduces the volume of embankment material significantly

*Increase the quality of soil compaction and more uniform

*Able to control and minimize differential settlement

*Distribute of the soil pressure evenly

Applications Of PP Biaxial Geogrid

PP Biaxial geogrids are suitable for reinforcing various embankments and roadbeds, slope protection, tunnel wall reinforcement, and permanent load-bearing foundation reinforcement in large airports, parking lots, docks, cargo yards, etc.

*PP Biaxial geogrid is used to increase the bearing capacity of road (ground) foundations and extend their service life.

*PP Biaxial geogrid is used to prevent the collapse or cracking of the road (ground) surface, keeping the ground looking neat and tidy.

*PP Biaxial geogrid is convenient for construction, time-saving, labor-saving, shortening the construction period and reducing maintenance costs.

*PP Biaxial geogrid is used to prevent cracks in culverts.

*PP Biaxial geogrid is used to reinforce soil slopes and prevent soil erosion.

*PP Biaxial geogrid is used to reduce the thickness of the cushion layer and save costs.

*PP Biaxial geogrid is used to support the stability of grass planting net pads on slopes for environmental greening.

What’s Asphalt Composite Grid ?

Lianyi® Asphalt Composite Grid Pavement Reinforcement System is manufactured at Feicheng Lianyi Engieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.Asphalt Composite Grid is a composite material consisting of fiberglass reinforcement grid coated in an elastomeric polymer,bonded to a non woven geotextile.Asphalt Composite Grid Lite is resistant to ultraviolet degradation and to biological and chemical environments normally found in soils.

Features Of Asphalt Composite Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Low elongation

*Thermal and chemical stability

Benefits Of Asphalt Composite Grid

*Universal application on milled surface or over existing pavement surfaces

*Quick and efficient installation

*Optimum asphalt retention of the nonwoven

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Asphalt Composite Grid

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

3.Self- Adhesive Fiberglass Geogrid

What’s Fiberglass Reinforcement Grid ?

Lianyi®Fiberglass Reinforcement Grid is manufactured at Feicheng Lianyi Engieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.Fiberglass Reinforcement Grid Rapid consists of a high stiffness fiberglass grid coated in an elastomeric polymer,a nonwoven geotextile and a thin self-adhesive bitumen layer.Fiberglass Reinforcement Grid is specially developed for very fast repairs with application on all types of surfaces without the need for tack coat saving time, labour and costs.Fiberglass Reinforcement Grid has a positive impact on reducing CO2, emissions due to its application and extension of maintenance periods.

Features Of Fiberglass Reinforcement Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Self-adhesive bitumen layer

*Low elongation

*Thermal and chemical stability

*Excellent milling performance

Benefits Of Fiberglass Reinforcement Grid

*Universal application on milled surfaces or over existing pavement surfaces

*Suitable for both asphalt and concrete surfaces

*Reinforcement of joint superstructures, single cracks and small asphalt areas

*Fast and easy manual installation

*Tack coat free application

*Self-adhesive bitumen layer

*No heating necessary

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Sand on the top of Rapid for good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Fiberglass Reinforcement Grid (https://geolianyi.com/product-category/product/geocomposite/fiberglass-geocomposite/)

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

3.Self- Adhesive Fiberglass Geogrid