Call us today!

Blog

Fiberglass Geogrid VS Polyester Geogrid

Fiberglass Geogrid: Known for its extremely high tensile strength and modulus (stiffness) at a low strain. It is inert to biological and chemical degradation but is susceptible to damage in alkaline environments and has lower resistance to installation damage. Its primary function is reflection crack inhibition in pavement overlays.

Polyester Geogrid: Known for its excellent long-term creep resistance and durability. It has high tensile strength and good flexibility, making it robust during installation. It is primarily used for soil reinforcement in demanding, long-term applications like retaining walls and steep slopes.

Difference of Fiberglass Geogrid and Polyester Geogrid

| Product Name | Fiberglass Geogrid | Polyester Geogrid |

| Material & Composition | Glass fiber filaments yarns coated with a protective polymer (e.g., PVC, acrylic). | Polyester (PET) yarns, typically coated with PVC or another polymer. |

| Chemical Structure | Inorganic, amorphous solid. | Organic polymer with ester functional groups. |

| Primary Characteristic | Very High Tensile Modulus (Extremely Stiff) | Excellent Creep Resistance |

| Tensile Behavior | High strength, low elongation (breaks at 3%-5% strain). Brittle behavior. | High strength, moderate elongation (breaks at 10%-15% strain). Ductile behavior. |

| Durability & Aging | Excellent resistance to acids, chemicals, and biological decay. Vulnerable to alkalis (e.g., cementitious environments). | Good general chemical resistance. Excellent long-term durability in most soil environments. |

| Installation Damage | More susceptible due to the brittleness of the glass fiber filaments yarns. Requires careful backfilling. | Highly resistant due to the flexibility and toughness of the polyester yarns. |

| Long-Term Performance | Strength can degrade over time in high-pH environments. Minimal creep under constant load. | The benchmark for creep resistance. Designed to maintain load for 75-120+ years without significant stretching. |

| Primary Function | Reinforcement & especially Reflection Crack Inhibition. | Soil Reinforcement. |

| Applications | • Asphalt Pavement Overlays (to delay reflection cracks) • Soil stabilization where high stiffness is immediately needed. | • Reinforced Soil Retaining Walls (MSE Walls) • Reinforced Steep Slopes • Base Reinforcement over soft subgrades |

In-Depth Explanation

1. Fiberglass Geogrid

How It Works: The incredible stiffness (high modulus) of fiberglass is its key asset. When placed between an old, cracked pavement and a new asphalt overlay, it absorbs the stress from the movement of the old pavement. It does this not by stretching, but by distributing the stress over a wider area, effectively “bridging” the crack and preventing it from propagating quickly to the surface. This process is called reflection crack inhibition.

•Advantages:

1.High Stiffness: Provides immediate, high tensile resistance with very little deformation.

2.Chemical Inertness: Performs well in acidic environments and is impervious to rot and mildew.

3.Lightweight: Easy to handle and install.

•Disadvantages:

1.Alkali Sensitivity: The Achilles’ heel of fiberglass. The glass fiber filaments yarns can be corroded by the high pH (alkalinity) present in cement-stabilized bases or Portland cement concrete. Special, more expensive coatings are required for these applications.

2.Brittleness: The glass fiber filaments yarns are inherently brittle, making the geogrid more vulnerable to damage during installation if not handled with care (e.g., from sharp rocks or equipment).

3.Creep Concerns: While it exhibits low creep due to its stiffness, its long-term load-bearing capacity in reinforcing soils is less proven than polyester’s.

2. Polyester Geogrid

How It Works: Polyester geogrids are the workhorse of Mechanically Stabilized Earth (MSE) structures. Their excellent creep resistance is the most critical property here. When used to reinforce a soil mass (like in a retaining wall), the geogrid must hold the load for the structure’s entire design life (often 75-100 years) without significantly stretching (creeping). Polyester geogrid is uniquely suited for this.

•Advantages:

1.Superior Creep Resistance: This is the single most important reason for choosing polyester for permanent soil reinforcement. It can sustain a high percentage of its ultimate strength for decades.

2.Durability & Toughness: Highly resistant to installation damage and have excellent long-term durability in a wide range of soil environments.

3.Flexibility: Conforms well to uneven subgrades and is easier to handle without fear of brittle fracture.

•Disadvantages:

1.Hydrolysis Risk: Polyester geogrid can degrade through a chemical process called hydrolysis, which is accelerated by high temperatures and high pH (alkaline) environments. However, modern geogrids are manufactured with specially formulated PET polymers and coatings that are highly resistant to hydrolysis, making them suitable for most soil conditions.

2.Lower Initial Stiffness: It is not as stiff as fiberglass and is therefore not the preferred choice for reflection crack control in pavements.

Conclusion:

The choice is driven by the primary function and design life of the structure.

For pavement overlay systems where the goal is to control reflective cracking, Fiberglass Geogrid is the specialized and most effective solution.

For permanent soil reinforcement structures like retaining walls and slopes, Polyester Geogrid is the industry standard due to its unparalleled long-term creep performance and durability.

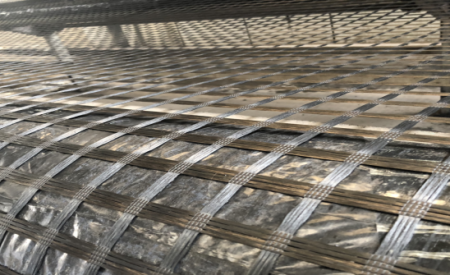

What’s Glass Fiber Geogrid?

Lianyi®Glass fiber geogrid is an excellent geosynthetic material used for road surface reinforcement,old road strengthening,and roadbed and soft soil foundation reinforcement.It is made of glass fiber through weaving and coating processes,featuring high strength,low elongation,high elastic modulus,resistance to high and low temperatures,alkali resistance,and aging resistance.Glass fiber geogrid is a bidirectional elastic geogrid used to control cracks through reflection.Fatigue and plastic deformation of asphalt concrete overlay. They have an asphalt coating to ensure the correct adhesion of geogrid mortar to asphalt.

Features Of Glass Fiber Geogrid

*High tensile strength from 30kN/m to 300kN/m

*Low elongation ≤3%

*Customized roll size,1*100m/roll,2*100m/roll,2.5*100m/roll,3.95*100m/roll,5.2*100m/roll,5.95*100m/roll etc.

*Customized mesh size,8.5*8.5mm,12.7*12.7mm,25.4*25.4mm,30*30mm,40*40mm,50*50mm etc.

*Simple construction,save cost.

Advantages Of Glass Fiber Geogrid

*Glass fiber geogrid increase the tensile strength of the asphalt layer to ensure its distribution under vertical loads.

*Uniform horizontal stress on a larger surface.

*Minimize reflective cracking caused by stress and temperature changes to the greatest extent.

*Enhance the fatigue resistance of the pavement under cyclic loads.

*Glass fiber geogrid offers cost-effectiveness by reducing the regular maintenance of flexible flooring.

*The use of glass fiber geogrid can increase the loading cycle by up to 12 times,reducing cracks and extending the service life of the road surface.

Applications Of Glass Fiber Geogrid

*Asphalt layer reinforcement.

*Repair the road surface.

*Urban roads, expressways and highways.

*Airport.

*Platforms and parking lots, etc.

3. Self- Adhesive Fiberglass Geogrid 4. Fiberglass Geocomposite

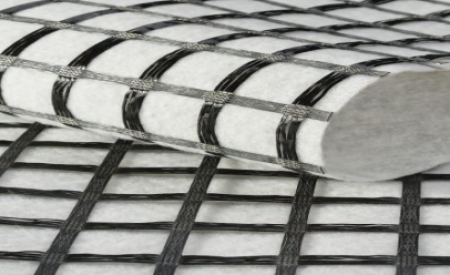

What’s Asphalt Reinforcement Geogrid?

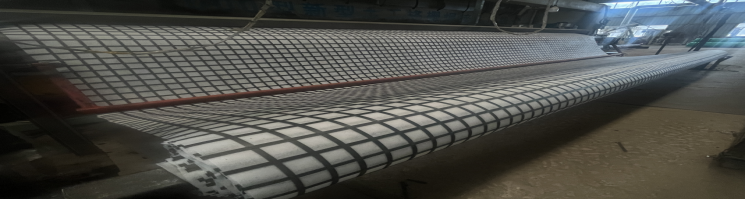

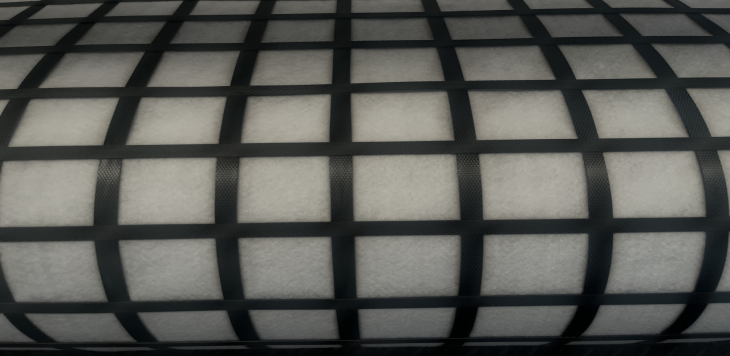

Lianyi®Asphalt Reinforcement Geogrid is high modulus glass fiber yarn associated with 17g/ m2 polyester or pp non woven geotextile,unique “warp knitting” technology ensures the immediate tension of the technical yarn,it provides 500g /m² emulsion excess (residual binder) to adapt to on-site conditions.

Features Of Asphalt Reinforcement Geogrid

*High tensile strength,from 30kN/m, to 300kN/m

*Low elongation,≤4%

*Mesh size from 12.7mm to 50mm

*Customized roll size,2*100m/roll,2.5*100m/roll,3.95*100m/roll,5*100m/roll,5.2*100m/roll

*Increasing asphalt tensile stress resistance

*Bearing a significant proportion of horizontal tension forces, thus ensuring even stress distribution over a large area

Advantages Of Asphalt Reinforcement Geogrid

*Asphalt Reinforcement Geogrid has flexible structure,suitable for frosted pavement

*Asphalt Reinforcement Geogrid has excellent adhesion,light veil enhances bonding

* Asphalt Reinforcement Geogrid increase road surface lifespan

* Asphalt Reinforcement Geogrid improving the quality of the asphalt pavement.

* Asphalt Reinforcement Geogrid reducing maintenance costs.

* Asphalt Reinforcement Geogrid preventing reflective cracking.

Applications Of Asphalt Reinforcement Geogrid

*Asphalt reinforcement

*Road pavement reinforcement

*Repair to prevent cracking

*Rehabilitation of damaged, crack control and prevention

*Trench, road widening

Keywords:

1. Asphalt Fiberglass Geogrid

2. Fiberglass Geogrid

3. Self- Adhesive Fiberglass Geogrid

4. Fiberglass Geocomposite

PP Biaxial Geogrid VS Triaxial Geogrid

PP Biaxial Geogrid: Best for stabilizing soft subgrades and reinforcing layered systems where the primary forces are in two, perpendicular directions (e.g., roads, foundations, retaining walls). It acts like a stiff,high-tensile reinforcement.

Triaxial Geogrid: Best for base course reinforcement over stable subgrades, especially where loads are multi-directional. It excels at confinement and interlock within granular aggregates, distributing loads more efficiently. It is the modern standard for paved and unpaved roads.

Difference of PP Biaxial Geogrid and Traxial Geogrid

| Product Name | PP Biaxial Geogrid | Triaxial Geogrid |

| Material & Structure | Polypropylene (PP). Punched sheet, drawn into a rectangular aperture grid. | Typically Polypropylene (PP) or Polyethylene (PE). Punched sheet, drawn and oriented into a stable, triangular aperture grid. |

| Aperture Shape | Rectangular or Square. | Triangular (Hexagonal). |

| Mechanical Action | Tensile Reinforcement & Separation. Provides high tensile stiffness in two main directions (machine & cross-machine). | Multi-directional Confinement & Interlock. Provides stiffness in multiple directions, offering superior radial stiffness. |

| Primary Function | Carries tensile loads to reduce deformation and improve overall stability. | Improves the performance of the aggregate layer itself by mechanically stabilizing it through confinement. |

| Key Property | High Tensile Modulus at low strain (e.g., 2% strain). | In-plane Stiffness and Aggregate Interlock. |

| Load Distribution | Good in two primary directions. | Excellent and uniform in all directions. More efficient at distributing loads, reducing vertical stress on the subgrade. |

| Applications | •Soil Reinforcement for Retaining Walls & Steep Slopes • Foundations over soft soil • Subgrade Stabilization | •Base Reinforcement for Paved & Unpaved Roads •Railway Ballast •Working platforms over stable subgrade •Applications with multi-directional traffic (e.g., parking lots, intermodal yards) |

| Advantages | •High tensile strength in primary directions. •Excellent for long-term reinforcement under constant load. •Cost-effective for its target applications. | • Reduces rutting more effectively. • Allows for reduced aggregate thickness. • Performs better under dynamic/cyclic loading. • Excellent resistance to installation damage. |

In-Depth Explanation

1. PP Biaxial Geogrid

•How It Works: The manufacturing process (punching and drawing) aligns the polymer molecules, creating a very stiff grid with high tensile strength in its two primary directions. When placed between two layers (e.g., between soft subgrade and a gravel base), it:

1.Separates the layers, preventing the intermixing of soils.

2.Resists Tensile Forces. As the soft soil beneath tries to deform, it induces tensile strain in the geogrid. The geogrid’s high stiffness resists this strain, spreading the load over a wider area via “membrane support.”

2. Triaxial Geogrid

•How It Works: The key is the triangular aperture geometry. This shape is inherently more stable and provides radial stiffness (stiffness in all directions in the plane of the grid. Its primary mechanism is confinement:

1.Mechanical Interlock: The angular aggregate particles partially penetrate the apertures and lock into place.

2.Confinement: The geogrid’s ribs prevent the aggregate particles from moving laterally when a load is applied. This confinement dramatically improves the bearing capacity of the aggregate layer itself, turning it into a “mechanically stabilized layer.”

3.Improved Load Distribution: The multi-directional stiffness distributes wheel loads through a wider angle, reducing the pressure reaching the weak subgrade.

Conclusion:

The choice is not about which product is “better” in an absolute sense, but which one is more effective for the specific engineering mechanism you require.

•For tensile reinforcement against global instability (walls, slopes, very soft ground), choose PP Biaxial Geogrid

. •For lateral confinement and stabilization of a granular layer (pavement base, working platforms), choose Triaxial Geogrid.

Keywords:

1. PP Geogrid

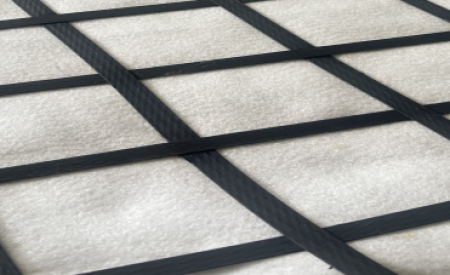

What’s Steel Plastic Geogrid Composite Geotextile?

Lianyi®Steel plastic geogrid composite geotextile is a high-performance geosynthetic material manufactured through advanced composite technology. It perfectly combines the high strength of steel plastic composite geogrid with the multi-functionality of geotextile, achieving an integrated function of “reinforcement, isolation, filtration and drainage”.Steel plastic geogrid composite geotextile has outstanding advantages such as fast construction, reliable quality and high comprehensive benefits, and is an important tool for solving complex foundation problems in modern civil engineering construction.

Core Structure and Composition

This material is usually composed of a three-layer structure, like a “sandwich” :

1.Core layer (reinforcing layer) : steel plastic composite geogrid

Material: With high-strength steel wire or iron wire as the core, and wrapped with polyethylene (PE) or polypropylene (PP) plastic on the outside to prevent corrosion.

Function: It provides extremely high tensile strength and shear strength at nodes, serving as the “skeleton” of the material and undertaking the primary reinforcing function.

2.Upper and lower layers (functional layer) : geotextile

Material: Usually needle punched nonwoven geotextile (polyester or polypropylene).

Function: It provides isolation, filtration, drainage (reverse filtration), protection and other functions.

3.Composite process

Geotextiles are firmly bonded to one or both sides of the steel plastic composite grid through processes such as thermal lamination, adhesive bonding or needling

Advantages Of Steel Plastic Geogrid Composite Geotextile

1.Integrated functions, effect 1+1>2:

*Reinforcement + isolation: One-time laying, simultaneously achieving the functions of reinforcement and stability as well as preventing the mixture of different soil layers.

*Reinforcement + filtration and drainage: While reinforcing, ensure that water in the foundation can be smoothly discharged laterally without soil particles being lost, maintaining the long-term stability of the structure.

2.Convenient construction and controllable quality

*The cumbersome process of laying geogrid and geotextiles layer by layer on site has been eliminated, and the construction efficiency has been greatly improved.

*Steel plastic geogrid composite geotextile avoids problems such as inaccurate positioning and material damage that may occur during on-site laying, making it easier to ensure the quality of the project.

*The integrated structure is easier to tension during laying and can immediately exert a reinforcing effect.

3.Performance enhancement

*Geotextile provides certain additional protection for the plastic coating of steel plastic geogrid

*The integrity after compounding is better, and the interlocking friction force with the soil is greater.

Applications Of Steel Plastic Geogrid Composite Geotextile

*Soft soil foundation treatment: Steel plastic geogrid composite geotextile is used for soft foundations in highways, railways, airports, ports, etc., to enhance bearing capacity and prevent settlement and collapse.

*Reinforced soil retaining wall/slope: As a reinforcing material,Steel plastic geogrid composite geotextile also ensures smooth drainage behind the wall, making it an ideal choice for constructing high and steep, stable structures.

*Reinforcement of embankments and riverbanks: Enhance the stability of embankments while preventing soil erosion.

*Large station foundations: such as container yards, logistics parks, parking lots, etc., bear heavy and repeated loads.

*Environmental protection projects: such as the base layer of landfill sites and the covering system for site closure, need to have the functions of reinforcement, isolation and protection simultaneously.

Keyword:

1. Welded Geogrid

4. Geotextile

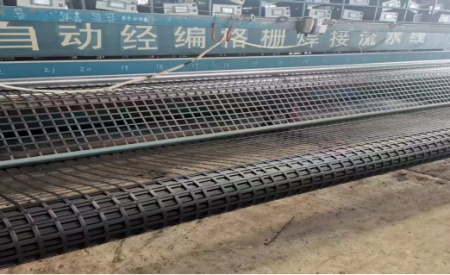

What’s Steel Plastic Composite Geogrid?

Lianyi®Steel plastic composite geogrid is a geosynthetic material with high-strength steel wire (or other metal wire) as the core load-bearing material, wrapped with plastic protective layers such as polyethylene (PE) or polypropylene (PP) on the outside, and made into a geogrid-like structure through precise processes (such as welding)

Steel plastic composite geogrid design ingeniously combines the high strength of metal with the corrosion resistance of plastic,the popular type 100-100kN/m,mesh size 75*75mm.

Features Of Steel Plastic Composite Geogrid

*Core force-bearing unit: The steel wire inside. This endows the grating with extremely high tensile strength (typically up to over 100 kN/m, far exceeding that of pure plastic geogrid)

*Protective layer: The plastic covering the outside.Its main function is to prevent corrosion and rust, ensuring that the internal steel wire can work stably for a long time in damp, acidic or alkaline soil environments and extending its service life.

*Node structure: Steel wires are strongly welded at the intersection points to form a firm and rigid node. This is the key to the superior performance of steel-plastic composite geogrid, It can ensure that it will not tear at the point of force application, and the force can be effectively transmitted and dispersed

.

Advantages Of Steel Plastic Composite Geogrid

Compared with pp geogrid, fiberglass geogrid,etc., steel plastic composite geogrid have the following outstanding advantages

*Ultra-high strength and low creep: It has extremely high tensile strength and small deformation (low creep) under high loads, providing long-term stable reinforcement.

*Outstanding durability: The plastic coating effectively resists chemical and electrochemical corrosion in soil and water, with a long designed service life.

*Rigid nodes with strong interlocking force: The interlocking and interlocking effect with the soil is excellent, which can maximize the self-strength of the soil and form a stable complex.

*Easy to install: It is relatively light in weight, easy to cut, connect and lay.

Applications Of Steel Plastic Composite Geogrid

The core function of steel plastic composite geogrid is “reinforcement”, that is, it utilizes its high tensile strength to withstand tensile stress in the soil, thereby enhancing the stability and load-bearing capacity of the soil. Mainly applied to:

1. Soft soil foundation treatment

*Scene: Soft foundations beneath highways, railways, airports, and port terminals.

*Function: Disperse the load, reduce uneven settlement, and prevent pavement cracking.

2. Reinforced soil retaining wall

*Scene: Cutting or embankment retaining walls of highways and railways, landscape retaining walls.

*Function: As a reinforcing bar, it works in conjunction with the panel and backfill soil to form stable upright or steep walls, saving land and earthwork.

3. Slope reinforcement and slope protection

*Scene: Roadbeds, reservoirs, and slopes of rivers.

*Function: Enhance the stability of slopes, prevent landslides and erosion, and allow for the construction of steeper slopes.

4. Large-scale ground foundation reinforcement

*Scene: Container yard, logistics park, parking lot, freight yard.

*Function: It can withstand the repeated loads of heavy containers and vehicles, prevent ground subsidence and surface layer damage.

Keyword:

1. Welded Geogrid