Call us today!

Blog

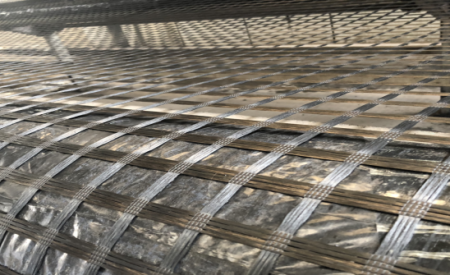

What’s Asphalt Composite Grid?

Lianyi®Asphalt Composite Grid is used for the reinforcement of asphalt overlays in the construction of new pavements and rehabilitation of existing pavements.

Asphalt Composite Grid is a composite consisting of bundles of glass filaments stitched onto a polypropylene paving fabric in both the longitudinal and transverse directions using polyester (PET) yarn.The glass fibres provide high tensile stiffness, and the polypropylene fabric provides a means of maintaining the required geometry of the composite, as well as a fixing layer during installation.Once installed and saturated with bitumen, the paving fabric then acts as a waterproofing layer and also as a stress absorbing membrane interface.

Asphalt Composite Grid is a composite interlayer comprising a punched and stretched polypropylene geogrid thermally bonded to a fabric backing.The fabric backing facilitates installation and provides a long-term sealing effect -once saturated with bitumen. Owing to the 3-dimensional geometry of the geogrid, the new asphalt layer is mechanically interlocked into the geogrid’s wide apertures, thus providing reinforcement, stress relief and sealing functions.

Asphalt Composite Grid is a large aperture or standard aperture composite, typically used at a lower structural level,under base course and binder course layers.

Asphalt Composite Grid is a composite interlayer comprising a grid of glass filament bundles stitch bonded to a non-woven fabric.The high modulus glass filaments provide high absorption of stress at low strains.After being saturated with bitumen the fabric performs a sealing function.Asphalt Composite Grid provides reinforcement, stress relief and sealing functions.

Asphalt Composite Grid is a composite interlayer comprising a glass yarn grid stitch bonded to a lightweight backing fabric. The high modulus glass filaments provide high absorption of stress at low strains. The lightweight backing fabric is only present to assist with adhesion during installation and subsequently permits intimate contact between overlying asphalt and the underlying surface.

Asphalt Composite Grid consists of a glass yarn grid combined with a polymer modified bitumen membrane.The underside of the Asphalt Composite Grid includes an adhesive coating, while the upper side is treated with a protective layer of quartz sand.The adhesive layer is protected during storage by a peel-off release film.

Asphalt Composite Grid consists of a polymer modified bitumen membrane that is treated on the surface with a quartz sand, and the underside is coated to protect the product for storage and handling.

Asphalt Composite Grid does not require specialist installation and can be affixed to most sound substrates using the adhesive coating on the Asphalt Composite Grid product, or alternatively can be installed by heat activating the Asphalt Composite Grid product using a flame torch.

Features Of Asphalt Composite Grid

*High tensile strength and low elongation

.

*Minimum viscous elongation in order to assure long term reductions in the incremental plastic deformation of the asphalt layer

*High flexibility and drapability

*Easy to fix to the support layer with a tack coat spray and good adhesion to the support

*The connection between the upper and lower asphalt layers is assured by the tack coat, without creating any separation

Advantages Of Asphalt Composite Grid

*Increase road service life and save cost

*Prevent fatigue cracking and reflection cracking

*High-temperature resistant rutting

*Reduced rutting

*Initial and long-term cost savings compared with traditional rehabilitation methods

*The optimal interlayer type for the solution due to our diverse range of interlayer products

Applications Of Asphalt Composite Grid

*Reinforced asphalt overlay

*Asphalt pavement reinforcement

*Asphalt road construction

Lianyi®PP Composite Geogrid is made up of biaxial geogrid-Polypropylene through the process of extruding, longitudinal and transverse heat stretching.Nonwoven Geotextile is then heat bonded to the grid to form a sound composite structure.PP Composite Geogrid is designed to prevent reflection cracking, water damage and improve load capacity in road construction and renovation.

PP Composite Geogrid has the property of high temperature resistance and anti-fatigue cracking and therefore extending the life and time of asphalt pavements.

Features Of PP Composite Geogrid

*High tensile strength from 15-15kN/m to 50-50kN/m

*Good elongation ≤13%

*Mesh size: 33*33mm,36*36mm,39*39mm,65*65mm

*High strength junctions and stiff ribs

*Good integrity,high node strength

*Stable performance,strong resistance to microorganisms and corrosion

Advantages Of PP Composite Geogrid

*Distribution of loads and therefore reducing stress concentration over the soil

*The geogrid’s structural junctions, rigid ribs and thick walls help lock aggregate, increasing its shear resistance.

*As a result when a vertical load is applied, the aggregate is restrained by the ribs reducing deformation

*Decrease in long term deformation

*Increase in load distribution

Applications Of PP Composite Geogrid

*Base reinforcement

*Subgrade reinforcement

*Pavement stabilisation

*Subgrade separation

*Embankment stabilisation

*Slope stabilisation

1. Geocomposite

2. Combigrid

What’s Asphalt Fiberglass Grid?

Lianyi®Asphalt Fiberglass Grid is an excellent geosynthetic material used for road surface reinforcement, old road strengthening, and roadbed and soft soil foundation reinforcement.Asphalt Fiberglass geogrid

is a semi-rigid product made of high-strength alkali-free glass fiber yarns through an internationally advanced warp knitting process to form a mesh base material, which is then coated on the surface. It features extremely high tensile strength in both the warp and weft directions and a relatively low elongation rate.Fiberglass geogrid also possesses excellent properties such as heat resistance, cold resistance, anti-aging, and corrosion resistance.Asphalt fiberglass grid is widely used in the reinforcement of asphalt pavements, cement pavements, and roadbeds, as well as in railway roadbeds, embankment slope protection, airport runways, and sand prevention and control projects.

Asphalt fiberglass grid is a kind of mesh structure material made of glass fiber yarns through certain weaving techniques. To protect the glass fiber yarns and improve the overall performance, it undergoes a special coating treatment process to form a geocomposite material.

Asphalt fiberglass grid is made by weaving and coating glass fiber filaments. Asphalt fiberglass grid feature extremely high tensile strength in both longitudinal and transverse directions, low elongation, high elastic modulus, and excellent resistance to high and low temperatures. After surface coating treatment, they possess superior alkali resistance and aging resistance, and are widely used in the reinforcement of asphalt pavements, cement concrete pavements, and roadbeds. It is applicable to both hard and flexible road surfaces. Compared with traditional road surfaces, it can reduce costs, extend service life and prevent reflective cracks on the road. Asphalt fiberglass grid can also be used for reinforcing soft soil in railways, airports, water conservancy projects, DAMS, etc., as well as for reinforcing road bases.

Features Of Asphalt Fiberglass Grid

*The main component of glass fiber is silicon oxide, which is an inorganic material. Its physical and chemical properties are extremely stable, and it features high strength, high modulus, excellent wear resistance, outstanding cold resistance, and no long-term creep. Good thermal stability; The reticular structure interlocks and restricts the aggregates. Enhance the load-bearing capacity of asphalt mixtures. Due to the special modified asphalt coating on the surface, it has dual composite performance, which greatly improves the wear resistance and shear capacity of the fiberglass geogrid .

.

*The product features high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance and long service life. It can enhance and strengthen the road surface, prevent rutting and fatigue cracking of the road surface It can resist thermal and cold expansion cracks and reflective cracks beneath, and disperse the load-bearing stress of the road surface, thereby extending the service life of the road surface. It has high tensile strength and low elongation, no long-term creep, good physical and chemical stability, good thermal stability, resistance to fatigue cracking, high-temperature rutting, low-temperature shrinkage cracking, and can delay and reduce reflective cracks.

*Sometimes, in combination with self-adhesive pressure-sensitive adhesive and surface asphalt impregnation treatment, the grid and the asphalt pavement are closely integrated into one. Due to the increased interlocking force of soil and stone materials within the fiberglass geogrid, the friction coefficient between them significantly increases (up to 0.8 to 10). The uplift resistance of the fiberglass geogrid buried in the soil is significantly enhanced due to the strong frictional biting force between the fiberglass geogrid and the soil. Therefore, it is an excellent reinforcing material. Meanwhile, fiberglass geogrid are a kind of lightweight and flexible plastic flat mesh material. They are easy to cut and connect on site and can also be overlapped and lapped. The construction is simple and does not require special construction machinery or professional technicians.

Advantages Of Asphalt Fiberglass Grid

*Slow down reflective cracks

Reflective cracks are caused by significant displacement of the old concrete surface layer near the joints or cracks, resulting in stress concentration within the asphalt overlay above it. They include horizontal displacement due to changes in temperature and humidity, as well as vertical shear displacement caused by traffic loads. The former leads to a relatively concentrated tensile stress within the asphalt overlay above the joint or crack. The latter subjects the asphalt overlay above the joint to greater flexural tensile stress and shear stress.

Due to the high modulus of fiberglass geogrid, reaching 67Gpa, they are applied as hard interlayers with high rigidity in asphalt overlay layers. Their function is to suppress stress, release strain, and at the same time, as reinforcing materials for asphalt concrete, enhance the tensile and shear strength of the overlay structure, thereby achieving the purpose of reducing cracks. Practical experience shows that the corresponding crack energy of a horizontal crack that has changed direction can move 0.6 meters from its starting point. Reinforcing materials with a width of more than 1.5 meters help ensure that the energy is completely dissipated on both sides of the crack.

*Resistance to fatigue cracking

The asphalt overlay on the old cement concrete pavement mainly serves to enhance the pavement’s functionality and makes little contribution to its load-bearing capacity. The rigid concrete pavement beneath the overlay still plays a crucial role in load-bearing. However, the asphalt overlay on the old asphalt concrete pavement is different. The asphalt overlay will bear the load together with the old asphalt concrete pavement. Therefore, when asphalt overlay is applied to asphalt concrete pavement, in addition to reflective cracks, fatigue cracking will also occur due to the long-term action of loads. We conducted a force analysis on the loading conditions of the asphalt overlay on the old asphalt concrete pavement: As the asphalt overlay is a flexible surface layer of the same nature as the asphalt overlay, the road surface will bend and sink when subjected to loads. The asphalt overlay layer in direct contact with the wheel is subjected to pressure, while the surface layer is subjected to tensile force outside the wheel load edge. Due to the different nature of the forces acting on the two force-bearing areas and their close proximity to each other, damage is prone to occur at the junction of the two force-bearing areas, that is, at the sudden change of force. Fatigue cracking occurs under the action of long-term loads.

In the asphalt overlay layer, fiberglass geogrid can disperse the above-mentioned compressive and tensile stresses, forming a buffer zone between the two stressed areas. Here, the stress changes gradually rather than suddenly, reducing the damage to the asphalt overlay layer caused by sudden stress changes. Meanwhile, the low elongation of the fiberglass geogrid

reduces the deflection of the road surface, ensuring that the road surface will not undergo excessive deformation.

*High-temperature resistant rutting

Asphalt concrete exhibits rheological properties at high temperatures, which are specifically manifested as: the surface layer of asphalt roads becomes soft and sticky in summer. Under the action of vehicle loads, depressions occur in the stressed area. After the vehicle loads are removed, the asphalt surface layer cannot fully recover to its pre-load condition, that is, plastic deformation occurs. Under the repeated rolling of vehicles, plastic deformation accumulates continuously, forming ruts. After analyzing the structure of the asphalt surface layer, it can be known that due to the rheological properties of asphalt concrete at high temperatures, and when subjected to loads, there is no mechanism in the surface layer that can restrict the movement of aggregates in the asphalt concrete, the asphalt surface layer is pushed, which is the main reason for the formation of ruts.

The use of fiberglass geogrid in the asphalt overlay layer serves as a framework in the asphalt surface layer. In asphalt concrete, aggregates run through the fiberglass geogrid, forming a composite mechanical interlocking system that restricts the movement of aggregates and increases the lateral restraint force in the asphalt overlay layer. The various parts of the asphalt surface layer check and balance each other, preventing the displacement of the asphalt surface layer and thus playing a role in resisting rutting.

*Resistant to low-temperature shrinkage cracking

In extremely cold regions, the surface temperature of asphalt roads in winter is close to the ambient temperature. Under such temperature conditions, asphalt concrete shrinks when cooled, generating tensile stress. When the tensile stress exceeds the tensile strength of asphalt concrete, cracks occur. Cracks develop in areas where they are concentrated, leading to diseases. From the perspective of the causes of cracks, the key to solving the problem lies in how to make the strength of asphalt concrete resist tensile stress.

The application of fiberglass geogrid in asphalt overlay layers significantly enhances the tensile strength of asphalt concrete, enabling it to withstand considerable tensile stress without failure. In addition, even if cracks occur in a local area, causing the stress at the crack site to be overly concentrated, the stress will gradually disappear through the transmission of the fiberglass geogrid, and the cracks will no longer develop into cracks. When selecting fiberglass geogrid, in addition to their performance indicators meeting the requirements of the above table, special attention should also be paid to ensuring that their width is not less than 1.5m, so as to have sufficient cross-sectional area when they are used as interlayers to control reflective cracks to fully dissipate crack energy. Meanwhile, the mesh size should be 0.5 to 1.0 times the maximum particle size of the asphalt surface layer material on it. This is conducive to achieving the best shear adhesive property and promoting the interlocking and confining of aggregates.

Lianyi®Asphalt Grid is a kind of mesh structure material made of glass fiber through certain weaving techniques. To protect the glass fiber yarns and improve the overall performance, it undergoes a special coating treatment process to form a geocomposite material.

Asphalt Grid is a new type of excellent geosynthetic base material for reinforcing road surfaces and roadbeds. This product is made by weaving and coating glass fiber filaments yarns.Asphalt Grid feature extremely high tensile strength in both longitudinal and transverse directions, low elongation, high elastic modulus, and excellent resistance to high and low temperatures. After surface coating treatment, they possess superior alkali resistance and aging resistance, and are widely used in the reinforcement of asphalt pavements, cement concrete pavements, and roadbeds. It is applicable to both hard and flexible road surfaces.Compared with traditional road surfaces, it can reduce costs, extend service life and prevent reflective cracks on the road. Asphalt Grid can also be used for reinforcing soft soil in railways, airports, water conservancy projects, DAMS, etc., as well as for reinforcing road bases.

*High tensile strength and low elongation – Asphalt Grid are made of glass fiber yarns and have a very high resistance to deformation, with a fracture elongation of less than 3%.

*No long-term creep – As a reinforcing material, the ability to resist deformation under long-term loads, that is, creep resistance, is extremely important. Asphalt Grid do not creep, which ensures that the product can maintain its performance for a long time.

*Thermal stability – The melting point of glass fiber yarns is above 1000℃, which ensures the thermal stability of the Asphalt Grid during the paving operation.

*Compatibility with asphalt mixture – The material coated on the Asphalt Grid in the post-treatment process is designed for asphalt mixture. Each fiber is fully coated, which has a high compatibility with asphalt. This ensures that the Asphalt Grid will not be isolated from the asphalt mixture in the asphalt layer but will be firmly combined together.

*Physical and chemical stability – After being coated with special post-treatment agents, Asphalt Grid can resist various physical wear and chemical erosion, as well as biological erosion and climate change, ensuring that their performance remains unaffected.

*Aggregate interlocking and confinement – As the Asphalt Grid is a mesh structure, the aggregates in the asphalt concrete can pass through it, thus forming mechanical interlocking.This restriction hinders the movement of aggregates, enabling the asphalt mixture to achieve a better compaction state, higher load-bearing capacity, better load transfer performance and less deformation under load.

*Reduced reflective and fatigue cracking

*Reduced rutting

*Extended pavement structural life

*Initial and long-term cost savings compared with traditional rehabilitation methods

*The optimal interlayer type for the solution due to our diverse range of interlayer products

*Large network of specialist installers and distributors

*Asphalt overlay reinforcement.

*Embankment slope protection

*Municipal roads, railway and highways.

*Airport runway

*Cement pavement

Fiberglass Geogrid VS Polyester Geogrid

Fiberglass Geogrid: Known for its extremely high tensile strength and modulus (stiffness) at a low strain. It is inert to biological and chemical degradation but is susceptible to damage in alkaline environments and has lower resistance to installation damage. Its primary function is reflection crack inhibition in pavement overlays.

Polyester Geogrid: Known for its excellent long-term creep resistance and durability. It has high tensile strength and good flexibility, making it robust during installation. It is primarily used for soil reinforcement in demanding, long-term applications like retaining walls and steep slopes.

Difference of Fiberglass Geogrid and Polyester Geogrid

| Product Name | Fiberglass Geogrid | Polyester Geogrid |

| Material & Composition | Glass fiber filaments yarns coated with a protective polymer (e.g., PVC, acrylic). | Polyester (PET) yarns, typically coated with PVC or another polymer. |

| Chemical Structure | Inorganic, amorphous solid. | Organic polymer with ester functional groups. |

| Primary Characteristic | Very High Tensile Modulus (Extremely Stiff) | Excellent Creep Resistance |

| Tensile Behavior | High strength, low elongation (breaks at 3%-5% strain). Brittle behavior. | High strength, moderate elongation (breaks at 10%-15% strain). Ductile behavior. |

| Durability & Aging | Excellent resistance to acids, chemicals, and biological decay. Vulnerable to alkalis (e.g., cementitious environments). | Good general chemical resistance. Excellent long-term durability in most soil environments. |

| Installation Damage | More susceptible due to the brittleness of the glass fiber filaments yarns. Requires careful backfilling. | Highly resistant due to the flexibility and toughness of the polyester yarns. |

| Long-Term Performance | Strength can degrade over time in high-pH environments. Minimal creep under constant load. | The benchmark for creep resistance. Designed to maintain load for 75-120+ years without significant stretching. |

| Primary Function | Reinforcement & especially Reflection Crack Inhibition. | Soil Reinforcement. |

| Applications | • Asphalt Pavement Overlays (to delay reflection cracks) • Soil stabilization where high stiffness is immediately needed. | • Reinforced Soil Retaining Walls (MSE Walls) • Reinforced Steep Slopes • Base Reinforcement over soft subgrades |

In-Depth Explanation

1. Fiberglass Geogrid

How It Works: The incredible stiffness (high modulus) of fiberglass is its key asset. When placed between an old, cracked pavement and a new asphalt overlay, it absorbs the stress from the movement of the old pavement. It does this not by stretching, but by distributing the stress over a wider area, effectively “bridging” the crack and preventing it from propagating quickly to the surface. This process is called reflection crack inhibition.

•Advantages:

1.High Stiffness: Provides immediate, high tensile resistance with very little deformation.

2.Chemical Inertness: Performs well in acidic environments and is impervious to rot and mildew.

3.Lightweight: Easy to handle and install.

•Disadvantages:

1.Alkali Sensitivity: The Achilles’ heel of fiberglass. The glass fiber filaments yarns can be corroded by the high pH (alkalinity) present in cement-stabilized bases or Portland cement concrete. Special, more expensive coatings are required for these applications.

2.Brittleness: The glass fiber filaments yarns are inherently brittle, making the geogrid more vulnerable to damage during installation if not handled with care (e.g., from sharp rocks or equipment).

3.Creep Concerns: While it exhibits low creep due to its stiffness, its long-term load-bearing capacity in reinforcing soils is less proven than polyester’s.

2. Polyester Geogrid

How It Works: Polyester geogrids are the workhorse of Mechanically Stabilized Earth (MSE) structures. Their excellent creep resistance is the most critical property here. When used to reinforce a soil mass (like in a retaining wall), the geogrid must hold the load for the structure’s entire design life (often 75-100 years) without significantly stretching (creeping). Polyester geogrid is uniquely suited for this.

•Advantages:

1.Superior Creep Resistance: This is the single most important reason for choosing polyester for permanent soil reinforcement. It can sustain a high percentage of its ultimate strength for decades.

2.Durability & Toughness: Highly resistant to installation damage and have excellent long-term durability in a wide range of soil environments.

3.Flexibility: Conforms well to uneven subgrades and is easier to handle without fear of brittle fracture.

•Disadvantages:

1.Hydrolysis Risk: Polyester geogrid can degrade through a chemical process called hydrolysis, which is accelerated by high temperatures and high pH (alkaline) environments. However, modern geogrids are manufactured with specially formulated PET polymers and coatings that are highly resistant to hydrolysis, making them suitable for most soil conditions.

2.Lower Initial Stiffness: It is not as stiff as fiberglass and is therefore not the preferred choice for reflection crack control in pavements.

Conclusion:

The choice is driven by the primary function and design life of the structure.

For pavement overlay systems where the goal is to control reflective cracking, Fiberglass Geogrid is the specialized and most effective solution.

For permanent soil reinforcement structures like retaining walls and slopes, Polyester Geogrid is the industry standard due to its unparalleled long-term creep performance and durability.

What’s Glass Fiber Geogrid?

Lianyi®Glass fiber geogrid is an excellent geosynthetic material used for road surface reinforcement,old road strengthening,and roadbed and soft soil foundation reinforcement.It is made of glass fiber through weaving and coating processes,featuring high strength,low elongation,high elastic modulus,resistance to high and low temperatures,alkali resistance,and aging resistance.Glass fiber geogrid is a bidirectional elastic geogrid used to control cracks through reflection.Fatigue and plastic deformation of asphalt concrete overlay. They have an asphalt coating to ensure the correct adhesion of geogrid mortar to asphalt.

Features Of Glass Fiber Geogrid

*High tensile strength from 30kN/m to 300kN/m

*Low elongation ≤3%

*Customized roll size,1*100m/roll,2*100m/roll,2.5*100m/roll,3.95*100m/roll,5.2*100m/roll,5.95*100m/roll etc.

*Customized mesh size,8.5*8.5mm,12.7*12.7mm,25.4*25.4mm,30*30mm,40*40mm,50*50mm etc.

*Simple construction,save cost.

Advantages Of Glass Fiber Geogrid

*Glass fiber geogrid increase the tensile strength of the asphalt layer to ensure its distribution under vertical loads.

*Uniform horizontal stress on a larger surface.

*Minimize reflective cracking caused by stress and temperature changes to the greatest extent.

*Enhance the fatigue resistance of the pavement under cyclic loads.

*Glass fiber geogrid offers cost-effectiveness by reducing the regular maintenance of flexible flooring.

*The use of glass fiber geogrid can increase the loading cycle by up to 12 times,reducing cracks and extending the service life of the road surface.

Applications Of Glass Fiber Geogrid

*Asphalt layer reinforcement.

*Repair the road surface.

*Urban roads, expressways and highways.

*Airport.

*Platforms and parking lots, etc.

3. Self- Adhesive Fiberglass Geogrid 4. Fiberglass Geocomposite