Call us today!

Blog

What’s Asphalt Composite Grid ?

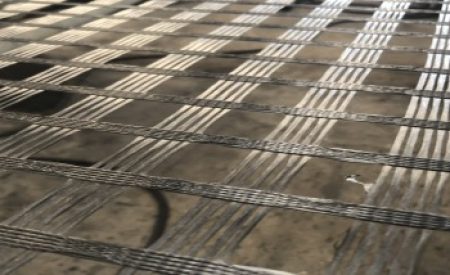

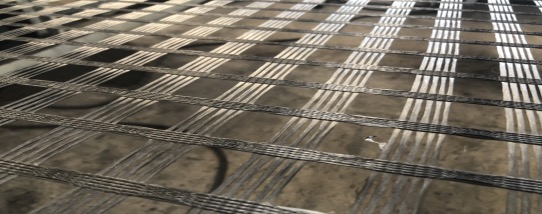

Lianyi® Asphalt Composite Grid Pavement Reinforcement System is manufactured at Feicheng Lianyi Engieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.Asphalt Composite Grid is a composite material consisting of fiberglass reinforcement grid coated in an elastomeric polymer,bonded to a non woven geotextile.Asphalt Composite Grid Lite is resistant to ultraviolet degradation and to biological and chemical environments normally found in soils.

Features Of Asphalt Composite Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Low elongation

*Thermal and chemical stability

Benefits Of Asphalt Composite Grid

*Universal application on milled surface or over existing pavement surfaces

*Quick and efficient installation

*Optimum asphalt retention of the nonwoven

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Asphalt Composite Grid

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

3.Self- Adhesive Fiberglass Geogrid

What’s Fiberglass Reinforcement Grid ?

Lianyi®Fiberglass Reinforcement Grid is manufactured at Feicheng Lianyi Engieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.Fiberglass Reinforcement Grid Rapid consists of a high stiffness fiberglass grid coated in an elastomeric polymer,a nonwoven geotextile and a thin self-adhesive bitumen layer.Fiberglass Reinforcement Grid is specially developed for very fast repairs with application on all types of surfaces without the need for tack coat saving time, labour and costs.Fiberglass Reinforcement Grid has a positive impact on reducing CO2, emissions due to its application and extension of maintenance periods.

Features Of Fiberglass Reinforcement Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Self-adhesive bitumen layer

*Low elongation

*Thermal and chemical stability

*Excellent milling performance

Benefits Of Fiberglass Reinforcement Grid

*Universal application on milled surfaces or over existing pavement surfaces

*Suitable for both asphalt and concrete surfaces

*Reinforcement of joint superstructures, single cracks and small asphalt areas

*Fast and easy manual installation

*Tack coat free application

*Self-adhesive bitumen layer

*No heating necessary

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Sand on the top of Rapid for good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Fiberglass Reinforcement Grid (https://geolianyi.com/product-category/product/geocomposite/fiberglass-geocomposite/)

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

3.Self- Adhesive Fiberglass Geogrid

Lianyi®Asphalt Glass Grid is the product for special application on surfaces covered by mastic asphalt. The product is manufactured at Feicheng Lianyi Engieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008. Asphalt Glass Grid is a high strength,open fiberglass grid custom knitted in a stable construction and coated with an elastomeric polymer. Every component of the matrix shall be stabilized against ultraviolet degradation and inert to chemicals normally found in a natural soil environment.

Properties Of Asphalt Glass Grid

*High grid stiffness provides a wrinkle-free installationand a direct load transmission

*Low elongation

*Thermal and chemical stability

*Excellent milling performance

Benefits Of Asphalt Glass Grid

*Elimination of flowing of mastic asphalt during the hardening

*Protection against microcracking in mastic asphalt

*Quick and efficient installation

*Easy cutting

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Asphalt Glass Grid

*Road widening

*Local repair

*Edge break cracking

*Concrete joints cracking

*Bridge repair

*Pavement joints

*Manholes

*Area-wide repair

*Localized cracking

Keywords:

1.Asphalt Fiberglass Geogrid

3.Self- Adhesive Fiberglass Geogrid

What’s Self Adhesive Fiber Glass Grid ?

Lianyi® Self Adhesive Fiber Glass Grid is manufactured at Feicheng LianyiEngieering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008. Self Adhesive Fiber Glass Grid is a high strength, open fiberglass grid custom knitted in a stable construction and coated with an elastomeric polymer and self-adhesive glue. Every component of the matrix shall be stabilized against ultraviolet degradation and inert to chemicals normally found in a natural soil environment.

Properties Of Self Adhesive Fiber Glass Grid

*High grid stiffness provides a wrinkle-free installation and a direct load transmission

*Low elongation

*Thermal and chemical stability

*Excellent milling performance

Benefits Of Self Adhesive Fiber Glass Grid

*Quick and efficient installation due to self-adhesive backing

*High grid stiffness providing a wrinkle free installation

*Easy cutting

*Good trafficability (suppliers, trucks, paver)

*Thermal and chemical stability

*Excellent milling performance

*Measured unlimited recyclability & enhanced properties in Reclaimed Asphalt Pavement (RAP)

Applications Of Self Adhesive Fiber Glass Grid

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

Keywords:

1.Asphalt Fiberglass Geogrid

3.Self- Adhesive Fiberglass Geogrid

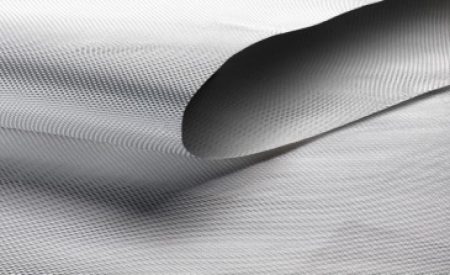

What‘s Woven Geotextile?

Lianyi®Woven Geotextile refers to geotextile produced by Weaving (also known as shuttling or Weaving) technology. It is composed of two sets of parallel yarns (warp yarns and weft yarns) interwoven at a 90-degree Angle, forming a fabric with stable structure and high strength. This type of geotextile, due to its excellent mechanical properties, is mainly applied in the fields of reinforcement and separation.

Production Process and Raw Materials

1.Raw materials

*Polypropylene (PP) or polyester (PET) are the most commonly used raw materials because they possess high strength, chemical resistance and microbial resistance.

*Yarn form: Usually, flat Yarns (Tape Yarns or Fibrillated Yarns), monofilament Yarns (single filament Yarns), and multi-filament yarns (multi-filament yarns) are used for weaving.

*Flat filament: Made by cutting and stretching plastic film, it is the most common form for manufacturing high-strength and low-cost woven geotextiles (similar to the material of plastic woven bags).

*Monofilament/multifilament: It can produce woven geotextiles with more uniform pores and better permeability, but the cost is usually higher.

2.Process: On a large loom, the warp and weft yarns are interwoven according to a specific structure (such as plain weave) to form a strong and dimensionally stable fabric roll.

Features Of Woven Geotextile

The performance characteristics of woven geotextiles are very distinct, which stems from their woven structure:

*High tensile strength and low elongation: These are its most prominent advantages. They can withstand extremely high loads with minimal deformation, making them highly suitable for projects that require reinforcement and stability.

*High modulus: It exhibits very high stiffness at the initial stage of force application.

*Excellent puncture and tear resistance: With a compact structure, it can effectively resist damage from rough fillers such as crushed stones.

*It exerts strength at a relatively low strain: It can provide effective reinforcement even when the soil undergoes very small deformation.

*Uniform and controllable pore size: By adjusting the yarn type and weaving density, products with different opening sizes (AOS) can be produced, but their porosity is usually lower than that of nonwoven geotextiles.

*Permeability: Its water permeability capacity depends on the size and number of pores. Compared with nonwoven geotextiles, its water flow conductivity (water conductivity) in the plane is usually better, but its permeability in the vertical direction is lower.

Functions and Applications Of Woven Geotextile

The core functions of woven geotextiles are “reinforcement” and “separation”, and sometimes they are also used for “filtration”, but careful selection is needed.

1.Reinforcement

Principle: By taking advantage of its high strength and low elongation characteristics, it disperses the load and enhances the overall stability and bearing capacity of the soil mass.

Application

*Road/railway subgrade on soft soil foundation: Laid on soft foundation to prevent the filling material from sinking and to disperse vehicle loads.

*Steep retaining walls and slope reinforcement: Combined with soil to form a solid composite structure, resisting earth pressure and landslides.

*Reinforced soil structure.

2.Separation

Principle: It is laid between two different types of materials (the lower layer of soft soil and the upper layer of crushed stone base) to prevent them from mixing with each other and maintain their respective structural integrity.

Application

Road base layer: Prevent the crushed stone base layer from sinking into the lower soft soil, while allowing water to pass through, and extend the service life of the road.

3.Filtration (conditional use)

Principle: Allow water to pass through while preventing excessive loss of soil particles. Woven geotextiles can achieve “unidirectional filtration” due to their relatively uniform pore diameters.

Application

It is used in situations that require high strength and high drainage performance, such as the drainage body wrapping of earth-rock DAMS and the gravel layer under coastal protection.

Keywords:

1.Woven Geotextile

What‘s Composite Geomembrane?

Lianyi®Composite geomembrane is a kind of geosynthetic material made by combining geomembrane (anti-seepage layer) and geotextile (protective layer) through methods such as hot pressing or adhesive bonding. It combines the excellent impermeability of geomembrane with the good mechanical properties and reverse filtration and drainage functions of geotextile.

Core Structure and Function

Composite geomembranes usually adopt a “sandwich” structure, generally being “one membrane and two fabrics” (one layer of geomembrane is compounded with one layer of geotextile on each side) or “one membrane and one fabric” (one layer of geomembrane is compounded with geotextile on only one side).

1.Core layer: Geomembrane

*Materials: Mainly high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC) and other polymers are used.

*Function: Provide core anti-seepage and isolation functions. Its permeability coefficient is extremely low (usually < 10⁻¹¹ cm/s), which can effectively prevent the leakage of water or contaminants.

2.Protective layer: Geotextile

*Material: Usually short-fiber or long-fiber non-woven fabric made of polyester (PET) or polypropylene (PP).

*Function

Protection: Prevent the geomembrane from being punctured by sharp objects such as sand, gravel, backfill soil, etc. on the upper and lower layers.

Drainage and exhaust: The non-woven fabric structure can guide and discharge pore water and gas parallel to the membrane surface, eliminate water vapor pressure, and prevent the membrane from being punctured.

Increase friction: Enhance the friction coefficient of the material surface, improve the stability of the contact surface with the soil, and prevent sliding during slope laying.

Features Of Composite Geomembrane

*It has excellent anti-seepage performance: this is its most core feature.

*Strong puncture and tear resistance: Geotextiles significantly enhance the mechanical strength of the overall material, making it more durable.

*High friction coefficient: It combines more firmly with the soil and has better slope stability.

*Convenient construction: The composite material can complete the two processes of anti-seepage and protection in one laying, which improves the construction efficiency.

Application Of Composite Geomembrane

Composite geomembrane is an indispensable material in modern anti-seepage projects and is widely used in:

*Water conservancy projects: Anti-seepage linings for reservoirs, DAMS, rivers and canals; Anti-seepage for water gates and pumping stations.

*Environmental protection project

*Landfill: As the base cushion layer and top cover layer, it prevents the leachate from garbage from polluting the underground soil and water bodies.

*Anti-seepage for regulating tanks, sedimentation tanks and evaporation ponds in sewage treatment plants.

*Tailings ponds and red mud storage yards: Prevent the leakage of harmful components from industrial waste residues.

*Traffic engineering: Anti-seepage isolation of highway and railway subgrades; Waterproofing for tunnel engineering.

*Construction engineering: Waterproofing and moisture-proofing for basements and rooftop gardens.

*Aquaculture: Anti-seepage linings for aquaculture ponds and fish ponds.

Precautions for Purchase and Construction

Index selection: Reasonable specifications should be chosen based on the engineering design requirements, including:

*Mass per unit area (e.g., 600g/m², 800g/m²)

*Geomembrane thickness (e.g., 0.5mm, 1.0mm)

*Breaking strength, tear strength, CBR puncture strength

*Permeability coefficient

*Welding process: After laying, the pieces need to be formed as a whole through hot wedge welding or hot air welding, and the weld seams should undergo strict non-destructive (air pressure testing) and destructive testing (sampling for tensile testing) to ensure the integrity of the anti-seepage system.

*Anchoring: Reliable anchoring treatment is required at the structural edge.

In summary,composite geomembrane is a high-performance engineering material that achieves a “1+1 > 2” effect through material composite technology. It integrates anti-seepage.