Call us today!

Blog

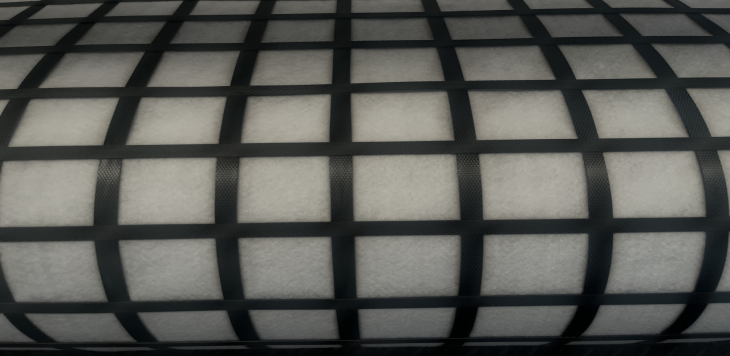

What’s Steel Plastic Composite Geogrid?

Lianyi®Steel plastic composite geogrid is a geosynthetic material with high-strength steel wire (or other metal wire) as the core load-bearing material, wrapped with plastic protective layers such as polyethylene (PE) or polypropylene (PP) on the outside, and made into a geogrid-like structure through precise processes (such as welding)

Steel plastic composite geogrid design ingeniously combines the high strength of metal with the corrosion resistance of plastic,the popular type 100-100kN/m,mesh size 75*75mm.

Features Of Steel Plastic Composite Geogrid

*Core force-bearing unit: The steel wire inside. This endows the grating with extremely high tensile strength (typically up to over 100 kN/m, far exceeding that of pure plastic geogrid)

*Protective layer: The plastic covering the outside.Its main function is to prevent corrosion and rust, ensuring that the internal steel wire can work stably for a long time in damp, acidic or alkaline soil environments and extending its service life.

*Node structure: Steel wires are strongly welded at the intersection points to form a firm and rigid node. This is the key to the superior performance of steel-plastic composite geogrid, It can ensure that it will not tear at the point of force application, and the force can be effectively transmitted and dispersed

.

Advantages Of Steel Plastic Composite Geogrid

Compared with pp geogrid, fiberglass geogrid,etc., steel plastic composite geogrid have the following outstanding advantages

*Ultra-high strength and low creep: It has extremely high tensile strength and small deformation (low creep) under high loads, providing long-term stable reinforcement.

*Outstanding durability: The plastic coating effectively resists chemical and electrochemical corrosion in soil and water, with a long designed service life.

*Rigid nodes with strong interlocking force: The interlocking and interlocking effect with the soil is excellent, which can maximize the self-strength of the soil and form a stable complex.

*Easy to install: It is relatively light in weight, easy to cut, connect and lay.

Applications Of Steel Plastic Composite Geogrid

The core function of steel plastic composite geogrid is “reinforcement”, that is, it utilizes its high tensile strength to withstand tensile stress in the soil, thereby enhancing the stability and load-bearing capacity of the soil. Mainly applied to:

1. Soft soil foundation treatment

*Scene: Soft foundations beneath highways, railways, airports, and port terminals.

*Function: Disperse the load, reduce uneven settlement, and prevent pavement cracking.

2. Reinforced soil retaining wall

*Scene: Cutting or embankment retaining walls of highways and railways, landscape retaining walls.

*Function: As a reinforcing bar, it works in conjunction with the panel and backfill soil to form stable upright or steep walls, saving land and earthwork.

3. Slope reinforcement and slope protection

*Scene: Roadbeds, reservoirs, and slopes of rivers.

*Function: Enhance the stability of slopes, prevent landslides and erosion, and allow for the construction of steeper slopes.

4. Large-scale ground foundation reinforcement

*Scene: Container yard, logistics park, parking lot, freight yard.

*Function: It can withstand the repeated loads of heavy containers and vehicles, prevent ground subsidence and surface layer damage.

Keyword:

1. Welded Geogrid