Call us today!

Blog

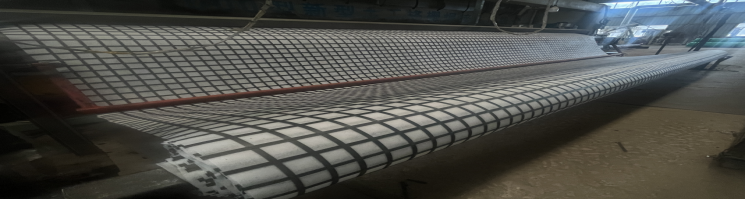

What’s Steel Plastic Geogrid Composite Geotextile?

Lianyi®Steel plastic geogrid composite geotextile is a high-performance geosynthetic material manufactured through advanced composite technology. It perfectly combines the high strength of steel plastic composite geogrid with the multi-functionality of geotextile, achieving an integrated function of “reinforcement, isolation, filtration and drainage”.Steel plastic geogrid composite geotextile has outstanding advantages such as fast construction, reliable quality and high comprehensive benefits, and is an important tool for solving complex foundation problems in modern civil engineering construction.

Core Structure and Composition

This material is usually composed of a three-layer structure, like a “sandwich” :

1.Core layer (reinforcing layer) : steel plastic composite geogrid

Material: With high-strength steel wire or iron wire as the core, and wrapped with polyethylene (PE) or polypropylene (PP) plastic on the outside to prevent corrosion.

Function: It provides extremely high tensile strength and shear strength at nodes, serving as the “skeleton” of the material and undertaking the primary reinforcing function.

2.Upper and lower layers (functional layer) : geotextile

Material: Usually needle punched nonwoven geotextile (polyester or polypropylene).

Function: It provides isolation, filtration, drainage (reverse filtration), protection and other functions.

3.Composite process

Geotextiles are firmly bonded to one or both sides of the steel plastic composite grid through processes such as thermal lamination, adhesive bonding or needling

Advantages Of Steel Plastic Geogrid Composite Geotextile

1.Integrated functions, effect 1+1>2:

*Reinforcement + isolation: One-time laying, simultaneously achieving the functions of reinforcement and stability as well as preventing the mixture of different soil layers.

*Reinforcement + filtration and drainage: While reinforcing, ensure that water in the foundation can be smoothly discharged laterally without soil particles being lost, maintaining the long-term stability of the structure.

2.Convenient construction and controllable quality

*The cumbersome process of laying geogrid and geotextiles layer by layer on site has been eliminated, and the construction efficiency has been greatly improved.

*Steel plastic geogrid composite geotextile avoids problems such as inaccurate positioning and material damage that may occur during on-site laying, making it easier to ensure the quality of the project.

*The integrated structure is easier to tension during laying and can immediately exert a reinforcing effect.

3.Performance enhancement

*Geotextile provides certain additional protection for the plastic coating of steel plastic geogrid

*The integrity after compounding is better, and the interlocking friction force with the soil is greater.

Applications Of Steel Plastic Geogrid Composite Geotextile

*Soft soil foundation treatment: Steel plastic geogrid composite geotextile is used for soft foundations in highways, railways, airports, ports, etc., to enhance bearing capacity and prevent settlement and collapse.

*Reinforced soil retaining wall/slope: As a reinforcing material,Steel plastic geogrid composite geotextile also ensures smooth drainage behind the wall, making it an ideal choice for constructing high and steep, stable structures.

*Reinforcement of embankments and riverbanks: Enhance the stability of embankments while preventing soil erosion.

*Large station foundations: such as container yards, logistics parks, parking lots, etc., bear heavy and repeated loads.

*Environmental protection projects: such as the base layer of landfill sites and the covering system for site closure, need to have the functions of reinforcement, isolation and protection simultaneously.

Keyword:

1. Welded Geogrid

4. Geotextile