Call us today!

Blog

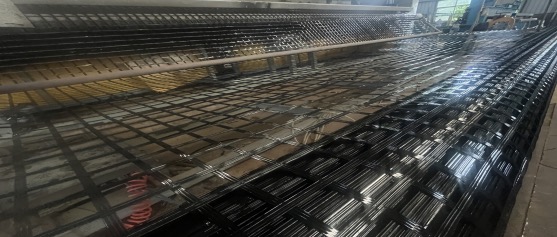

Lianyi®PET welded geogrid (polyester welded geogrid)is a kind of geosynthetic material with a mesh structure made mainly of polyethylene terephthalate (PET) through high-frequency welding or ultrasonic welding processes. It features high strength, corrosion resistance, fatigue resistance and other characteristics, and is widely used in engineering fields such as roadbed reinforcement, slope protection and soft foundation treatment.

Features Of PET Welded Geogrid

*High strength: It has a high tensile strength (up to 30 to 200kN/m), which can effectively disperse the load and prevent soil cracking.

*Low elongation: Small deformation under force (generally ≤8%), suitable for projects with strict deformation requirements.

*Corrosion resistance: PET material is resistant to acid, alkali, salt and microbial erosion, and is suitable for complex geological environments.

*Anti-aging: Add UV inhibitors to extend outdoor service life.

*Lightweight and easy to install: It is lighter than steel-plastic grating and has a higher laying efficiency.

*Environmentally friendly and recyclable: PET materials can be partially recycled and reused, in line with the trend of green engineering.

Common Types Of PET Welded Geogrid

The longitudinal (main force direction) strength is high, while the transverse strength is relatively low.

It is applicable to unidirectional force-bearing projects such as retaining walls and steep slope reinforcement.

The strength is balanced in both longitudinal and transverse directions, making it suitable for scenarios that require uniform force distribution, such as roadbeds and soft foundation treatment.

*Woven PET geogrid (non-welded type)

It adopts weaving technology, has better flexibility and is suitable for irregular terrain.

Application Of PET Welded Geogrid

*Reinforcement of highway/railway subgrades

*Reduce settlement, prevent reflective cracks and extend the service life of roads.

*Slope protection and reinforcement

*Enhance the anti-sliding capacity of soil and prevent landslides.

*Soft soil foundation treatment

*It forms a composite layer with the soil to enhance the bearing capacity.

*Airport runways, port storage yards

*Distribute the load to prevent ground cracking.

*Landfill sites, tailings ponds

*As a reinforcing layer, it enhances stability.

Key points of Construction

*Base treatment

Clear sharp objects and level the ground to prevent the geogrid from being punctured.

*Laying direction

The main strength direction (unidirectional geogrid) should be perpendicular to the force direction (such as slope).

*Lap joint and fixation

The lap width should be no less than 10cm and be fixed with U-shaped nails or binding.

*Filling and compaction

Fill the soil in layers to avoid direct mechanical compaction of the grid.

Notes

*Avoid prolonged exposure to ultraviolet rays and cover when storing.

*Avoid direct mechanical rolling during construction to prevent the welding points from breaking.

*Select the appropriate strength grade to ensure the safety of the project.

PET welded geogrids,with their advantages of high strength,corrosion resistance and easy construction, have become important materials in modern geotechnical engineering, especially suitable for projects with high requirements for weight and environmental protection.

Keywords:

1.Welded Geogrid