Call us today!

Blog

Warning: Undefined property: WP_Error::$parent in /www/wwwroot/geolianyi.com/wp-content/plugins/woocommerce/includes/class-wc-breadcrumb.php on line 269

Warning: Undefined property: WP_Error::$term_id in /www/wwwroot/geolianyi.com/wp-content/plugins/woocommerce/includes/class-wc-breadcrumb.php on line 273

What’s PP Continuous Filament Nonwoven Geotextile?

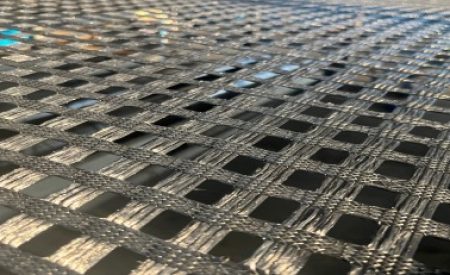

Lianyi®Polypropylene continuous filament needle punched nonwoven geotextile is formed by using high-quality polypropylene fiber as the main raw material through processes such as spinning, slit drawing, web laying, spraying, unique elliptical needling, and stretching and shaping. PP continuous filament needle punched nonwoven geotextile features excellent chemical properties, acid and alkali resistance, and physical and mechanical performance.PP needle punched nonwoven geotextile has high strength, large elongation, and high puncture and tear strength.PP nonwoven geotextile has a very broad range of application scenarios in projects such as railways,water conservancy, highways, airports, landfill sites, and tailings ponds.

Classification Of PP Continuous Filament Nonwoven Geotextile

*Polyester Continuous Filament Non Woven Geotextile

Features Of PP Continuous Filament Nonwoven Geotextile

*The world’s first 6.5-meter ultra-wide PP continuous filament needle punched nonwoven geotextile

reduces splicing, facilitates construction, and can lower the overall project cost

*The specific gravity of PP (polypropylene) non woven geotextile at room temperature is 0.91, while that of PET (polyester) non woven geotextile is 1.38. Under the same unit area mass conditions, polypropylene non woven geotextile contains more fibers, has more consolidation points, and has higher mechanical properties

*PP continuous filament needle punched nonwoven geotextile’s single-fiber strength is high,and the overall physical and mechanical indicators are higher than those of polyester non woven geotextiles

*PP continuous filament needle punched nonwoven geotextile has good chemical resistance and can be stably used within the PH range of 2 to 13. In engineering polypropylene continuous filament non woven geotextiles that come into direct contact with cement, fly ash, lime, etc., it can be stably used for a long time.Traditional polyester non woven geotextiles will hydrolyze until they disappear and completely lose their function

*Polypropylene continuous filament needle punched non woven geotextile has excellent freeze-thaw resistance and is suitable for use in high-cold permafrost areas

*Compared with traditional polyester non woven geotextiles , polypropylene non woven geotextiles are environmentally friendly, durable and pollution-free

Keyword:

1. Geotextile

Lianyi® Asphalt Grid is fiber glass yarns manufactured for asphalt reinforcement of paved surfaces.Asphalt grid is designed to prevent reflective cracking and reinforce asphalt pavements,providing strength and rigidity in a high strength glass fiber grid .

Asphalt grid is typically installed under the pavement’s wearing course and is designed to reinforce the surface course.It dissipates induced tensions which can lead to the risk of cracks,and can delay their appearance on the surface.

Asphalt grid is an engineered geogrid that is suitable for flexible road pavements,asphalt pavement and overall soil reinforcement.When properly installed,it offers a long design life,excellent performance and predictable in suit behaviour.

Classification Of Asphalt Grid

*Self Adhesive Fiberglass Geogrid

*Lowers maintenance costs

*Repairs severely cracked roads and postpones complete reconstruction

*Dramatically extends the life of roads, runways and parking lots

*Open aperture design promotes aggregate interlock between paving courses, greatly decreasing shear potential that is common with paving fabrics

*High stiffness, high modulus of elasticity, low elongation

*Effective bonding of grid during installation to leveling the prepared surface or course with patented adhesive backing(standard practice of use of tack coat is recommended to enhance or promote bonding between lifts of asphalt layers)

*Ease of constructability allows for asphalt grid installation and immediate placement of overlying pavement

*Asphalt reinforcement

*Reduce reflective cracking

*Prevent traffic induced shearing

*Extend road life

Keyword:

1. Asphalt Fiberglass Geogrid

Lianyi® PET Geogrid is a high strength coated geogrid manufactured from high tenacity polyester(PET) yarns,knitted to form a structured grid.PET Geogrid is used to reinforce soils where extremely high tensile strength with low elongation is required.The range of PET Geogrid is from 20kN/m-1000kN/m suitable for solving complex engineering problem.

PET Geogrid strength and stiffness are affected both by temperature and by rate or duration of loading.Therefore,it is important that standard methods of tensile testing are used,so that temperature and strain rate are defined.

PET Geogrid’s tensile strength and high molecular weight offer both vertical and horizontal soil reinforcement,and it’s proprietary UV-stabilized coating compound provides enhanced durability against the elements.

*Low elongation (below 13%) and high tensile strength (up to 1000 kN/m)

*Width up to 6.0m

*Industry leading stress-strain values with low elongation

*Improves modulus values of pavement base layers

*Design lifespan of 100 years

*Reinforced soil walls

*Embankment reinforcement

*Retaining structures

*Below structural foundations

*Basal reinforcement

*Piling platforms

*Reinforced steep soil slopes

*Subgrade improvement

Keywords:

1. PET Geogrid

Lianyi® PET Grid is a high performance pavement reinforcement geogrid that is engineered with industry leading stress-strain values to provide higher tensile strength resistance at low elongation and strength of 20kN/m to 1000kN/m.Coupled with a high degree of interaction with the infill material,PET grid offers the best value for pavement reinforcement when compared with any other competitive solution.

PET Grid is manufactured of polyester yarns that have a high molecular weight and tensile strength.These yarns are knitted into a dimensionally stable network of apertures to form a grid shape which offers tensile reinforcement to the soil in both the vertical and horizontal directions.PET grid is coated with black PVC coating to provide further chemical and mechanical benefits that preserve its durability in any environment.

*6 meter width for low overlap and reduced wastage

*Improves modulus values of pavement base layers

*Reduction in pavement crust thickness

*Easy installation,speedy construction and smaller carbon footprint

*Save up to 15-20% cost compared to conventional methods

*Basal reinforcement over soft soils

*Pavement reinforcement and optimization

*Below structural foundations

*Load transfer platform and void spanning

*Landslide repair

*Piling platforms

*Reinforced steep slopes

*Reinforced Foundations

Keywords:

1. PET Geogrid

Methodology Of Installation

Road Preparation

Complete crack sealing, pothole filling, base repairs, leveling course application, etc.

Broad Surface Condition

*Surface must be: dry, clean and dust-free.

*The road surface temperature must be between 5℃ and 60 ℃

*On asphalt surfaces less than 24 hours old, the surface temperature must be between 5℃ & 50 ℃

*Local guidelines should be followed for paving temperature range

Product Preparation

In order to preserve adhesive properties, fiberglass geogrid must be stored inside a dust-free environment and kept dry at the job site. Fiberglass geogrid must not be transported or stored at temperatures greater than 82 ℃

Methods For Installation

A. With Pressure Sensitive Adhesive

*Load roll onto front or back of tractor. Always load in such a way that allows the placement of mesh with the self-adhesive side down.

*Roll only with a rubber-tired roller to activate adhesive. Roller tyres must be kept clean.

*Apply tack coat/emulsion as per project requirements and pave once cured

B. Without Pressure Sensitive Adhesive

*Apply the track coat/emulsion in accordance with project specifications.Once the tack coat/emulsion has cured, proceed with the laying of glass fiber grid .

*Load roll onto front or back of tractor.Always load in such a way that allows the placement of glass fiber grid without any wrinkles.

*Roll only with rubber-tired roller and pave the asphalt layer.

Important Notes

*Because fiberglass geogrid is considered a skin irritant, workers should wear gloves while handling fiberglass geogrid.

*Asphalt Fiberglass grid can be custom cut to fit around structures by using a sharp utility knife.

*Asphalt Fiberglass grid must be applied without ripples. Sufficient tensile strength during application will eliminate this problem.

*Overlap at end of roll joints 75-100mm. Ensure that the overlaps are shingled in the direction of paving.

*Overlap longitudinal joints 50-75mm.

*Prior to paving, only construction and emergency vehicles shall be allowed to drive on installed asphalt fiberglass grid.

*Damaged sections shall be removed and patched, taking care to underlap the full roll.

*All glass fiber grid placed in a day shall be covered with asphalt immediately, within permissible laying temperatures to a minimum compacted thickness of 40mm.

*Avoid pushing of the asphalt delivery vehicles with the paver, particularly on uphill gradients.

*Prevent asphalt delivery vehicles from executing sharp turns, accelerating or braking on the glass fiber geogrid .

Keywords:

1. Fiberglass Geogrid

What’s Asphalt Pavement Reinforcement Grid?

Glass Fiber Grid’s open design incorporates fiberglass strands coated in a proprietary asphalt compatible chemical, which significantly reduces the sear potential often preent in other paving textiles & encourages aggregate interlock between paving courses. Glass fiber Grid is simple to install, delays the need for a whole rebuild, and reduces maintenance expenses.

Advantages

*Because of the self-adhesive backing, installation is quick and efficient.

*High grid stiffness providing a wrinkle-free installation.

*Thermal and chemically stable.

*Outstanding performance while milling

*Simple cutting

2. Fiberglass Composite Geogrid

Asphalt composite grid seamlessly integrates the formidable tensile strength inherent in our standard glass fiber grid styles with strategically incorporated non woven geotextile, forming a reliable moisture barrier upon saturation with tack/emulsion. Asphalt composite grid presents a range of versatile options encompassing standard paving non woven geotetxile fabric(which can be customized).

Advantages

*All-purpose, use over pre-existing pavement surfaces or on milled surfaces.

*Fast and effective installation.

*Easy cutting

3. Fiberglass Geogrid Composite With Nonwoven Geotetxile

Asphalt Composite Grid pavement reinforcement and moisture barrier system is manufactured at Feicheng Lianyi Engineering Plastics Co.,Ltd facility that has achieved ISO 9001:2015 certification and meets the requirements of EN 15381:2008.This asphalt composite grid consists of a fiberglass reinforcement grid coated in asphalt compatible polymer, bonded to a lightweight non woven paving geotextile. Glass fiber composite grid is resistant to ultraviolet degradation and to biological and chemical environments normally found in soils.

Advantages

*Quick and efficient installation.

*Efficient moisture barrier due to the non woven geotextile fabrics saturation with tack coat/emulsion.

*High grid stiffness providing a wrinkle free installation.

*Easy cutting

*Good trafficability (suppliers,trucks,paver).

*Thermal and chemical stability

*Excellent milling performance

4.Asphalt Reinforcement Fiberglass Paving Geogrid

Asphalt Reinforcement Glass Fiber Paving Geogrid is an advanced geosynthetic material design to enhance the durability and performance of asphalt overlays. Constructed from high strength, continuous fiberglass coated with an asphalt compatible polymer and embedded between two layers of non woven geotextile, Feicheng Lianyi Engineering Plastics Co.Ltd offrers superior performance compared to traditional paving non woven geotextile fabrics.

The fiberglass core provides 3 to 6 times greater tensile strength than conventional paving non woven geotextile fabrics, effectively distributing stress and reducing crack formation. Feicheng Lianyi Engineering Plastics Co.Ltd forms a robust, moisture resistant membrane, preventing water infiltration that can weaken the pavement structure. It is resistant to rot, mildew, and chemical degradation, ensuring long term durability in various environmental conditions. The material maintains dimensional stability and does not shrink or deform when exposed to hot mix asphalt, ensuring consistent performance during application. Compared to traditional paving methods, asphalt reinforcement glass fiber paving geogrid offers a more economical solution by extending the lifespan of asphalt overlays and reducing maintenance needs.

Advantages

*Easy to install and can be used on milled surfaces.

*Higher tensile strength for delayed reflective cracking.

*Strong waterproofing membrane.

*Life cycle coat savings can be realized through reduced maintenance intervals.

*No creep for reliable, long term performance.

Applications Of Asphalt Pavement Reinforcement Geogrid

Asphalt pavement reinforcement geogrid find application in a range of infrastructure projects, including roads, highways, bridges, runways, and parking units.

Keywords:

1. Asphalt Fiberglass Geogrid