Call us today!

Blog

What’s Steel Plastic Geogrid Composite Geotextile?

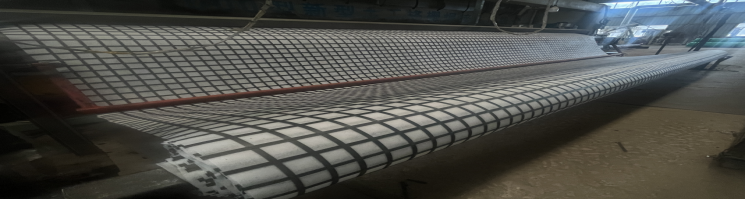

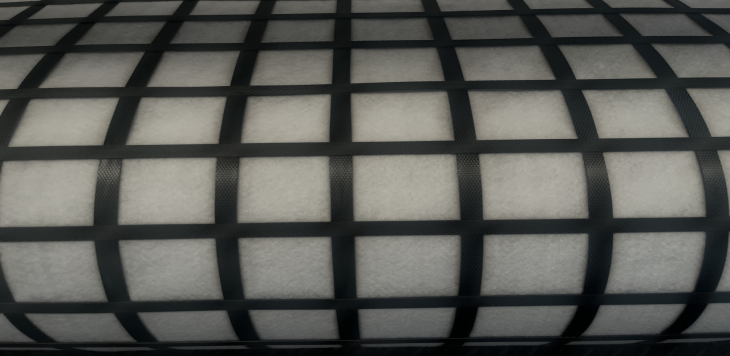

Lianyi®Steel plastic geogrid composite geotextile is a high-performance geosynthetic material manufactured through advanced composite technology. It perfectly combines the high strength of steel plastic composite geogrid with the multi-functionality of geotextile, achieving an integrated function of “reinforcement, isolation, filtration and drainage”.Steel plastic geogrid composite geotextile has outstanding advantages such as fast construction, reliable quality and high comprehensive benefits, and is an important tool for solving complex foundation problems in modern civil engineering construction.

Core Structure and Composition

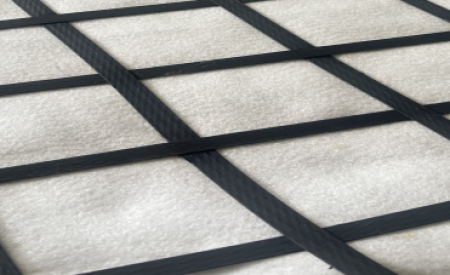

This material is usually composed of a three-layer structure, like a “sandwich” :

1.Core layer (reinforcing layer) : steel plastic composite geogrid

Material: With high-strength steel wire or iron wire as the core, and wrapped with polyethylene (PE) or polypropylene (PP) plastic on the outside to prevent corrosion.

Function: It provides extremely high tensile strength and shear strength at nodes, serving as the “skeleton” of the material and undertaking the primary reinforcing function.

2.Upper and lower layers (functional layer) : geotextile

Material: Usually needle punched nonwoven geotextile (polyester or polypropylene).

Function: It provides isolation, filtration, drainage (reverse filtration), protection and other functions.

3.Composite process

Geotextiles are firmly bonded to one or both sides of the steel plastic composite grid through processes such as thermal lamination, adhesive bonding or needling

Advantages Of Steel Plastic Geogrid Composite Geotextile

1.Integrated functions, effect 1+1>2:

*Reinforcement + isolation: One-time laying, simultaneously achieving the functions of reinforcement and stability as well as preventing the mixture of different soil layers.

*Reinforcement + filtration and drainage: While reinforcing, ensure that water in the foundation can be smoothly discharged laterally without soil particles being lost, maintaining the long-term stability of the structure.

2.Convenient construction and controllable quality

*The cumbersome process of laying geogrid and geotextiles layer by layer on site has been eliminated, and the construction efficiency has been greatly improved.

*Steel plastic geogrid composite geotextile avoids problems such as inaccurate positioning and material damage that may occur during on-site laying, making it easier to ensure the quality of the project.

*The integrated structure is easier to tension during laying and can immediately exert a reinforcing effect.

3.Performance enhancement

*Geotextile provides certain additional protection for the plastic coating of steel plastic geogrid

*The integrity after compounding is better, and the interlocking friction force with the soil is greater.

Applications Of Steel Plastic Geogrid Composite Geotextile

*Soft soil foundation treatment: Steel plastic geogrid composite geotextile is used for soft foundations in highways, railways, airports, ports, etc., to enhance bearing capacity and prevent settlement and collapse.

*Reinforced soil retaining wall/slope: As a reinforcing material,Steel plastic geogrid composite geotextile also ensures smooth drainage behind the wall, making it an ideal choice for constructing high and steep, stable structures.

*Reinforcement of embankments and riverbanks: Enhance the stability of embankments while preventing soil erosion.

*Large station foundations: such as container yards, logistics parks, parking lots, etc., bear heavy and repeated loads.

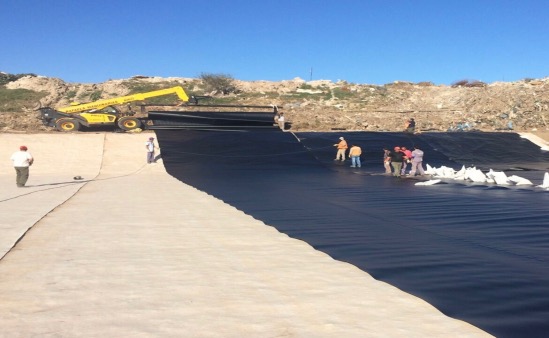

*Environmental protection projects: such as the base layer of landfill sites and the covering system for site closure, need to have the functions of reinforcement, isolation and protection simultaneously.

Keyword:

1. Welded Geogrid

4. Geotextile

What’s Steel Plastic Composite Geogrid?

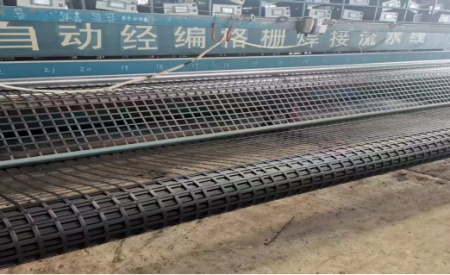

Lianyi®Steel plastic composite geogrid is a geosynthetic material with high-strength steel wire (or other metal wire) as the core load-bearing material, wrapped with plastic protective layers such as polyethylene (PE) or polypropylene (PP) on the outside, and made into a geogrid-like structure through precise processes (such as welding)

Steel plastic composite geogrid design ingeniously combines the high strength of metal with the corrosion resistance of plastic,the popular type 100-100kN/m,mesh size 75*75mm.

Features Of Steel Plastic Composite Geogrid

*Core force-bearing unit: The steel wire inside. This endows the grating with extremely high tensile strength (typically up to over 100 kN/m, far exceeding that of pure plastic geogrid)

*Protective layer: The plastic covering the outside.Its main function is to prevent corrosion and rust, ensuring that the internal steel wire can work stably for a long time in damp, acidic or alkaline soil environments and extending its service life.

*Node structure: Steel wires are strongly welded at the intersection points to form a firm and rigid node. This is the key to the superior performance of steel-plastic composite geogrid, It can ensure that it will not tear at the point of force application, and the force can be effectively transmitted and dispersed

.

Advantages Of Steel Plastic Composite Geogrid

Compared with pp geogrid, fiberglass geogrid,etc., steel plastic composite geogrid have the following outstanding advantages

*Ultra-high strength and low creep: It has extremely high tensile strength and small deformation (low creep) under high loads, providing long-term stable reinforcement.

*Outstanding durability: The plastic coating effectively resists chemical and electrochemical corrosion in soil and water, with a long designed service life.

*Rigid nodes with strong interlocking force: The interlocking and interlocking effect with the soil is excellent, which can maximize the self-strength of the soil and form a stable complex.

*Easy to install: It is relatively light in weight, easy to cut, connect and lay.

Applications Of Steel Plastic Composite Geogrid

The core function of steel plastic composite geogrid is “reinforcement”, that is, it utilizes its high tensile strength to withstand tensile stress in the soil, thereby enhancing the stability and load-bearing capacity of the soil. Mainly applied to:

1. Soft soil foundation treatment

*Scene: Soft foundations beneath highways, railways, airports, and port terminals.

*Function: Disperse the load, reduce uneven settlement, and prevent pavement cracking.

2. Reinforced soil retaining wall

*Scene: Cutting or embankment retaining walls of highways and railways, landscape retaining walls.

*Function: As a reinforcing bar, it works in conjunction with the panel and backfill soil to form stable upright or steep walls, saving land and earthwork.

3. Slope reinforcement and slope protection

*Scene: Roadbeds, reservoirs, and slopes of rivers.

*Function: Enhance the stability of slopes, prevent landslides and erosion, and allow for the construction of steeper slopes.

4. Large-scale ground foundation reinforcement

*Scene: Container yard, logistics park, parking lot, freight yard.

*Function: It can withstand the repeated loads of heavy containers and vehicles, prevent ground subsidence and surface layer damage.

Keyword:

1. Welded Geogrid

Lianyi®HDPE Geocell is a connected HDPE sheet/strip with a strong three-dimensional shape resembling a wasp nest that ties together, holds and stabilizes the soil. After geocell is filled with material, the geocell will prevent mass movement and increase the material stiffness.The layer on geocell will form a rigid and strong layer of structure so that it will resist the load laterally

*HDPE Geocell features free expansion and contraction, can be folded during transportation, and can be stretched into a grid during construction. When filled with loose materials such as soil, crushed stones, and concrete, it forms a structure with strong lateral restraint and high rigidity.

*HDPE Geocell is lightweight, wear-resistant, chemically stable, resistant to light and oxygen aging, acid and alkali resistant, and suitable for different soil and desert conditions.

*HDPE Geocell has high lateral restraint and anti-skid, anti-deformation, effectively enhancing the bearing capacity of the roadbed and the load dispersion effect.

*By altering the geometric dimensions such as the height and weld spacing of geocell, different engineering requirements can be met.

*HDPE Geocell can be extended and retracted freely and has a small transportation volume. Convenient connection and fast construction speed

*On the slope, geocell can prevent soil surface erosion

*On the road body, geocell can stabilize and increase the carrying capacity of soft subgrade

*Drainage protection

*Geocell has better carrying capacity and distributed loads

*Geocell is easy and fast to install

*Durable

*Retaining wall

*Basal reinforcement

*Slope stability

*Tree root protection

*Road construction

Lianyi®HDPE Geomembrane is made from the highest quality resin of High Density Polyethylene(HDPE), so it can meet the needs of very high material specifications as a safe containment system. This material is manufactured with strictly computerized quality control as the manufacturer guarantee all of quality with a civil responsibility insurance,

*HDPE Geomembrane has high resistant to chemicals,acids,and wastes,making it suitable for groundwater protection applications against all kinds of wates.

*HDPE Geomembrane also resistant to ultraviolet and extreme temperature changes so it also can be exposed safely for water reservoirs application.

*The flexibility of HDPE Geomembrane is ideal for highly contoured application like hills, detailed pools, and soil surface that could have a differential settlement.

*HDPE Geomembrane is available in both smooth and textured surfaces, and is also available in various thicknesses.

Advantages Of HDPE Geomembrane

*HDPE Geomembrane is known for its large strength to density ratio

*The density of HDPE Geomembrane can range from 930 to 970 kg/m3

*Although the density of HDPE Geomembrane is only marginally higher than that of low-density polyethylene, HDPE Geomembrane has little branching, giving it stronger intermolecular forces and tensile strength than LDPE.

*The difference in strength exceeds the difference in density, giving HDPE geomembrane a higher specific strength.

*HDPE Geomembrane is also harder and more opaque and can withstand somewhat higher temperatures.

Applications Of HDPE Geomembrane

*Landfill

*Water treatment plant

*Clean water reservoir

*Road construction on expansive

*Anti-seepage of the bottom lining of tailings

*Fishpond, swimming pool

What’s Non Woven Geotextile?

Lianyi®Non Woven Geotextile is one of geosynthetic that has opeing size with high permeability characteristic.Non Woven Geotextile is manufactured from needle punched Polyester or Polypropylene staple fiber or continuous filament.As a superior product of non woven geotextile,it has been designed and produced through long experience so that it performs perfectly on site for soil mechanics application.

Features Of Non Woven Geotextile

*Non woven geotextile mechanical properties that offer maximum strength in all directions throughout the length and width of every roll

*Unique manufacturing process utilizing both mechanical and thermal bonding processes ensures that the non woven geotextile offers superior performance

*Waterflows normal to the plane that are generally several times more than that required by design

*Non woven geootextile hydraulic properties that stimulate the build up of a natural soil filter in the adjacent soil and so ensure long term filtration stability.

Advantages Of Non Woven Geotextile

*Separator

Non Woven Geotextile will perform best as a separator between two layers of different material properties to avoid intermixing

*Filter and drainage

Non Woven Geotextile can retain any kind of soil material,but still allow water flow in and out.This means,clogging on the drainage media can be avoided.When applied as a filter under rip-rap,this material can also withstand soil fills and keeps passing water so that there will be no increase in hydrostatic pressure that can reduce the stability of the embankment

*Non Woven Geotextile is not specifically designed as reinforcement,it possesses sufficient tensile strength

*Geomembrane protection layer

Geomembrane is an impermeable geosynthetic material,that is susceptible to hazard puncture by static or dinamic force.Non Woven Geotextile provides maximum protective function so that the geomembrane will perform optimally as an impermeable layer during its operational period

Applications Of Non Woven Geotextile

*As a general purpose separator for use under site access roads and areas of hardstanding

*As a separation and strengthening layer under new roadways, car parks, industrial units etc.

*As a filter surround in the construction of a French drain or granular drainage blanket

*For separation: to prevent the intermixing of dissimilar soil layers

*For filtration: to allow the passage of fluids whilst preventing the uncontrolled passage of soil

Keyword:

1. Geotextile

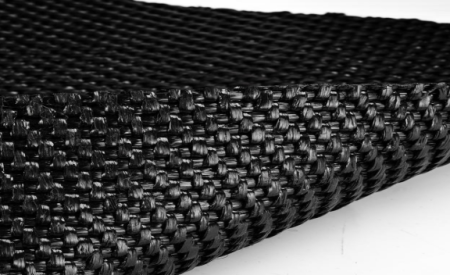

What’s Woven Geotextile?

Lianyi®Woven Geotextile is a woven geotextile product composed of woven silt film polypropylene tape. With the support of geotechnical knowledge and also sophisticated production equipment.Woven Geotextile can be used as a separator between selected fill and soft soil base,and it also serves as a reinforcement.

Features Of Woven Geotextile

*Provides superior reinforcement strength and soil interaction with high water flow and soil retention capabilities

*Offers premium confinement and reduces lateral movement of base materials

*Increases load distribution Resists punctures and common installation damages

*Panels can be factory- or field-seamed for efficient installation

Advantages Of Woven Geotextile

*High tear resistance properties,so that it can be installed on its best performance

*The surface of the woven geotextile has high friction to provide a large pull-out resistance when installed on cohesive soil.The higher the friction of the surface,the shorter anchorage length required for the reinforcement and vice versa.This will provide significant economic benefits

*Carbon black content that serves as UV stabilizer assures woven geotextile provides long enough resistance exposed to UV until it is covered by vegetation

*Tensile strength is an important parameter for reinforcement applications,hence woven geotextile provides maximum tensile strength at minimal material weight.This advantage contributes to the economic aspect while also gaining the expected level of structural stability

Applications Of Woven Geotextile

*As a filter wrap to granular drainage trenches and blankets

*As an erosion control layer under rock armor or concrete revetments in river & coastal defence systems

*As a filter layer in the construction of artificial sports surfaces and all-weather horse riding arenas

Keywords:

1.Geotextile