Call us today!

Blog

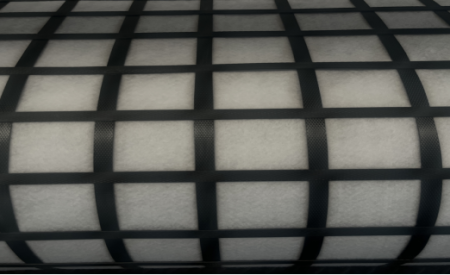

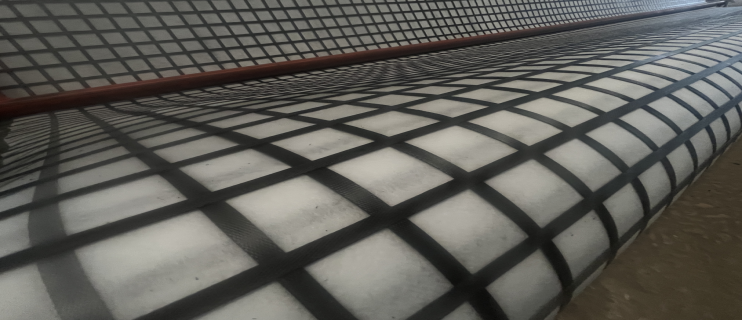

Lianyi®PP welded geogrid(polypropylene welded geogrid) is a kind of geosynthetic material with a mesh structure made mainly of polypropylene (PP) through hot-melt welding technology. It features light weight, corrosion resistance and low cost, and is widely used in fields such as roadbed reinforcement, slope protection and water conservancy projects.

*Lightweight and high strength: Moderate tensile strength (20 to 100kN/m), light weight, convenient for transportation and construction.

*Chemical resistance: PP material is resistant to acids, alkalis, salts and microbial erosion, and is suitable for damp or chemically polluted environments

*Good flexibility: Compared with steel-plastic grating, PP grating has a stronger deformation capacity and can adapt to uneven settlement.

*Low cost: The raw material prices are relatively low, and its economic efficiency is superior to that of PET or glass fiber geogrid.

*UV resistance (optional) : By adding UV inhibitors, the outdoor service life can be prolonged.

*Environmentally friendly and recyclable: PP material can be recycled and reused, meeting the requirements of sustainable development.

Common Types Of PP Welded Geogrid

It has high longitudinal strength but low transverse strength, and is suitable for unidirectional force-bearing projects such as retaining walls and steep slope reinforcement.

The strength is balanced in both longitudinal and transverse directions, making it suitable for scenarios that require uniform force distribution, such as soft foundation treatment and roadbed reinforcement.

Embed fibers or grids in the PP substrate to enhance the overall strength.

Application Of PP Welded Geogrid

*Reinforcement of highway/railway subgrades

*Reduce settlement and prevent road surface cracking.

*Slope protection and ecological restoration

*Combined with grass planting net pads, it is used for greening slope projects.

*Soft soil foundation treatment

*Enhance the bearing capacity of the foundation and prevent lateral displacement.

*River slope protection and embankment reinforcement

*Strong water resistance, suitable for water conservancy projects.

*Protection of anti-seepage layers for landfill sites and tailings ponds

*As a reinforcing layer, it protects the anti-seepage membrane.

Keywords:

1.Welded Geogrid

Lianyi® Geomembrane is a kind of geosynthetic material with extremely low water permeability, mainly made of high-molecular polymers (such as plastics, rubber, etc.). Essentially, it is an artificial anti-seepage roll material, similar to a huge “plastic sheet”, but its performance, durability and engineering characteristics are far beyond those of ordinary plastic sheets.

Main Raw Materials and Types

According to the different polymer materials used, geomembranes are mainly classified into the following categories:

1.HDPE (High-density Polyethylene) geomembrane

*Features: Strong resistance to chemical corrosion, excellent UV aging resistance, high tensile strength, and a wide range of operating temperatures. It is currently the most widely used and largest in quantity type.

*Appearance: Usually black (with carbon black added to enhance anti-aging properties), and there are also other colors such as green, blue, etc.

*Applicable scenarios: Landfill sites, sewage treatment plants, tailings ponds, hazardous waste disposal sites and other projects with extremely high requirements for anti-seepage.

2.LLDPE (Linear low-density Polyethylene) geomembrane

*Features: Softer and more flexible than HDPE, better resistance to stress cracking, and stronger adaptability to uneven settlement.

*Applicable scenarios: Artificial lakes, landscape water systems, aquaculture, underground projects and other projects that require good deformation adaptability.

3.PVC (polyvinyl chloride) geomembrane

*Features: Good flexibility, easy to weld, and relatively low cost. However, it has poor UV resistance and usually requires the addition of plasticizers (there may be a problem of long-term migration aging).

*Applicable scenarios: Channel seepage prevention, reservoirs, temporary coverage, etc.

4.Other types: such as EPDM (Ethylene Propylene diene monomer rubber) geomembrane (with excellent cold resistance), CPE (chlorinated polyethylene) geomembrane , etc., are used in some special occasions.

*Anti-seepage and isolation: This is its most core function. It can effectively prevent the migration of liquids (water, sewage, chemical solutions) and gases, and at the same time separate two geosynthetic materials with different properties.

*Durability: High-quality geomembranes have excellent resistance to chemical corrosion, ultraviolet rays and aging, and their designed service life can reach over 50 years.

*High strength and elongation: It can withstand certain construction tensile stress and foundation settlement deformation during the service period.

*High cost-effectiveness: Compared with traditional clay anti-seepage layers, it has significant advantages such as thin thickness, light weight, fast construction speed, and saving land space and cost.

Geomembrane is an indispensable material in modern environmental geotechnical engineering and is widely used in

*Environmental protection project

*Landfill: As the anti-seepage layer for the base and roof, it prevents leachate from polluting the underground soil and water bodies.

*Anti-seepage for regulating tanks, anaerobic tanks and oxidation ponds in sewage treatment plants.

*Hazardous waste disposal site: Safely isolate harmful substances.

*Water conservancy projects

*Reservoirs, artificial lakes and rivers: Prevent water resource leakage.

*Channel: Anti-seepage of irrigation channels to enhance the efficiency of water resource utilization.

*Mining Engineering

*Tailings pond: Prevent tailings water containing heavy metals and other harmful substances from seeping into the ground.

*Municipal and Landscape Engineering

*Roof garden: Waterproof and root-proof.

*Landscape water pools and golf course ponds.

*Moisture-proofing and waterproofing for basements and tunnels.

*Aquaculture industry

*The bottom protection and seepage prevention of aquaculture ponds facilitate water level control and water quality management.

*Agriculture

*Anti-seepage for water storage cellars and irrigation water tanks.

Key Technical Points for Construction

The performance of geomembranes is highly dependent on correct construction. Key links include:

*Base layer treatment: The foundation must be level, compacted and smooth, free of tree roots, sharp stones and other sharp objects to prevent the geotextile membrane from being punctured.

*Laying: Carry out the laying when the weather is good, relax the laying to avoid stress concentration, and leave sufficient expansion and contraction allowance.

*Welding: This is the most crucial technology. The coils are joined into a single unit by using double-track hot melt welding (to form cavities for pressure detection) and extruded electrode welding (for detailed areas and repairs).

Detection

*Non-destructive testing: Conduct pneumatic testing (for double-track welding) or vacuum box testing (for extrusion welding) on all welds to check the sealing performance.

*Destructive testing: On-site weld seam samples are cut and sent to the laboratory for shear and peel strength tests.

*Protection: After laying is completed, a protective layer (such as geotextile, sand, etc.) should be covered in time to prevent direct sunlight and mechanical damage.

Common Misunderstandings and Precautions

It’s not the case that the thicker the better: The appropriate thickness (commonly 0.5mm – 3.0mm) and material of the geomembrane should be selected based on the engineering design requirements (such as water head pressure and foundation conditions).

The quality of materials is of vital importance: One should choose a brand with a good reputation and check its relevant certifications and test reports.

Professional construction is the key: “Three parts materials, seven parts construction.” It must be carried out by an experienced construction team with professional equipment; otherwise, even the best materials will not be able to play their role.

Summary

Geomembrane is a highly efficient and reliable new type of anti-seepage material, and it is a key technical product for solving problems such as environmental pollution control, water resource conservation, and infrastructure construction. Its successful application is a systematic project, which requires strict control over every link from material selection, design, construction to quality inspection.

Keyword:

1.Geomembrane

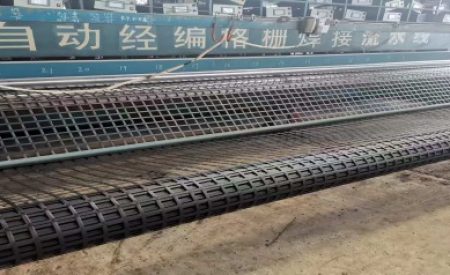

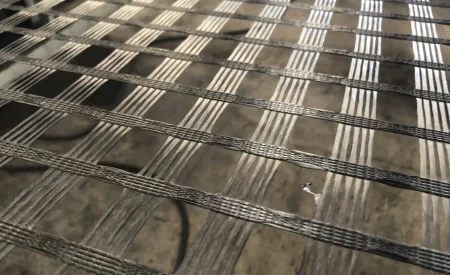

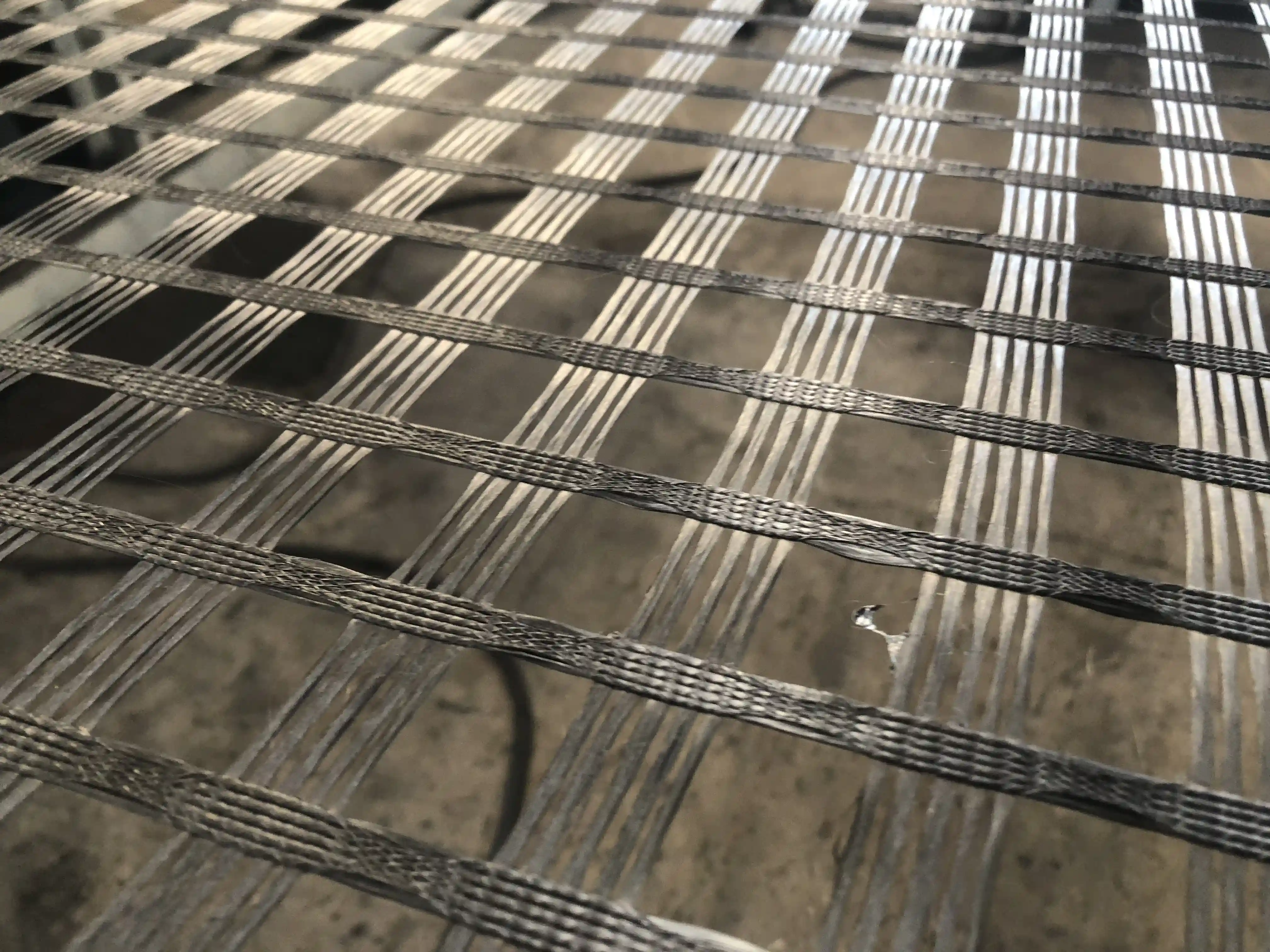

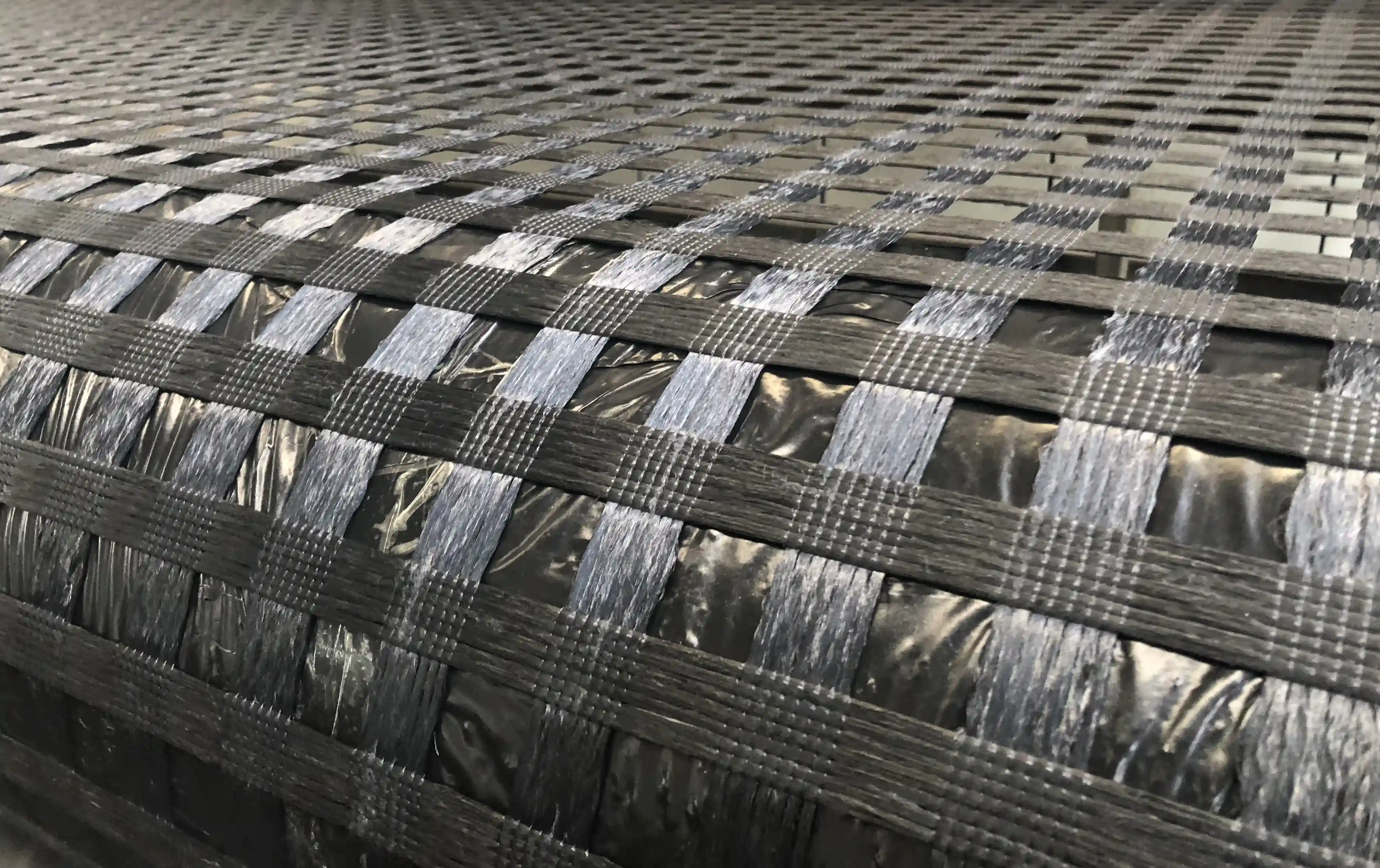

Lianyi®PET welded geogrid (polyester welded geogrid)is a kind of geosynthetic material with a mesh structure made mainly of polyethylene terephthalate (PET) through high-frequency welding or ultrasonic welding processes. It features high strength, corrosion resistance, fatigue resistance and other characteristics, and is widely used in engineering fields such as roadbed reinforcement, slope protection and soft foundation treatment.

Features Of PET Welded Geogrid

*High strength: It has a high tensile strength (up to 30 to 200kN/m), which can effectively disperse the load and prevent soil cracking.

*Low elongation: Small deformation under force (generally ≤8%), suitable for projects with strict deformation requirements.

*Corrosion resistance: PET material is resistant to acid, alkali, salt and microbial erosion, and is suitable for complex geological environments.

*Anti-aging: Add UV inhibitors to extend outdoor service life.

*Lightweight and easy to install: It is lighter than steel-plastic grating and has a higher laying efficiency.

*Environmentally friendly and recyclable: PET materials can be partially recycled and reused, in line with the trend of green engineering.

Common Types Of PET Welded Geogrid

The longitudinal (main force direction) strength is high, while the transverse strength is relatively low.

It is applicable to unidirectional force-bearing projects such as retaining walls and steep slope reinforcement.

The strength is balanced in both longitudinal and transverse directions, making it suitable for scenarios that require uniform force distribution, such as roadbeds and soft foundation treatment.

*Woven PET geogrid (non-welded type)

It adopts weaving technology, has better flexibility and is suitable for irregular terrain.

Application Of PET Welded Geogrid

*Reinforcement of highway/railway subgrades

*Reduce settlement, prevent reflective cracks and extend the service life of roads.

*Slope protection and reinforcement

*Enhance the anti-sliding capacity of soil and prevent landslides.

*Soft soil foundation treatment

*It forms a composite layer with the soil to enhance the bearing capacity.

*Airport runways, port storage yards

*Distribute the load to prevent ground cracking.

*Landfill sites, tailings ponds

*As a reinforcing layer, it enhances stability.

Key points of Construction

*Base treatment

Clear sharp objects and level the ground to prevent the geogrid from being punctured.

*Laying direction

The main strength direction (unidirectional geogrid) should be perpendicular to the force direction (such as slope).

*Lap joint and fixation

The lap width should be no less than 10cm and be fixed with U-shaped nails or binding.

*Filling and compaction

Fill the soil in layers to avoid direct mechanical compaction of the grid.

Notes

*Avoid prolonged exposure to ultraviolet rays and cover when storing.

*Avoid direct mechanical rolling during construction to prevent the welding points from breaking.

*Select the appropriate strength grade to ensure the safety of the project.

PET welded geogrids,with their advantages of high strength,corrosion resistance and easy construction, have become important materials in modern geotechnical engineering, especially suitable for projects with high requirements for weight and environmental protection.

Keywords:

1.Welded Geogrid

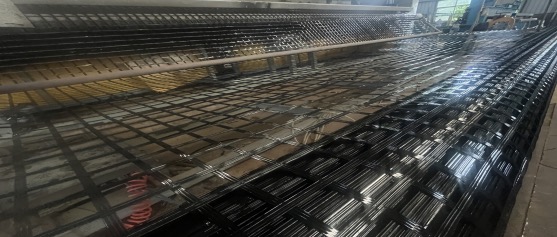

What‘s Steel Plastic Composite Geogrid ?

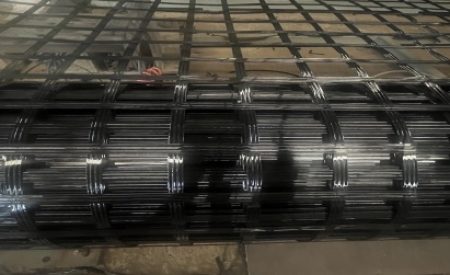

Lianyi®Steel Plastic Composite Geogrid is a kind of high-strength geosynthetic material, which is made by combining high-strength Steel wire with polyethylene (PE) or polypropylene (PP), and it combines the mechanical properties of metal with the corrosion resistance of polymer.

Features Of Steel Plastic Composite Geogrid

*High strength: The steel wire core offers extremely high tensile strength (up to over 100kN/m), making it suitable for withstanding heavy loads.

*Mesh size: 50*50mm,60*60mm,75*75mm,100*100mm,120*120mm,150*150mm

*Corrosion resistance: The plastic coating protects the steel wire from the erosion of acids, alkalis, salts and groundwater, thus extending its service life.

*Small deformation: Low elongation (generally ≤3%), which can effectively restrain soil deformation and improve structural stability.

*Good durability: Stable performance in complex environments (such as humidity and ultraviolet rays), with a long service life.

*Lightweight and easy to install: Light in weight, convenient to cut, and highly efficient in laying.

Advantages Of Steel Plastic Composite Geogrid

*The ultra-high tensile strength can reach 30 to 150 kN/m (much higher than that of plastic geogrid), and it is used in heavy-duty engineering.

*The deformation rate of the low creep steel wire core material is less than 3% (almost no deformation under long-term loading).

*The corrosion-resistant plastic layer isolates water/oxygen/chemical media, with a design life of ≥50 years (applicable to saline-alkali land and landfill sites).

*The large interfacial friction coefficient, rough surface structure, enhanced interlocking force with soil (friction Angle > 25°).

*Flexible rolls (1 to 6 meters wide) with convenient construction can be cut on site and have high laying efficiency.

Application Of Steel Plastic Composite Geogrid

*Highway/railway subgrade: Distribute loads, prevent uneven settlement, and reduce cracks.

*Slope protection: Enhance the anti-sliding capacity of soil, such as embankments and mine slopes.

*Soft soil foundation treatment: Form a composite layer with soil to enhance bearing capacity.

*Reinforcement of retaining walls: Reduce lateral pressure and enhance the integrity of the structure.

*Airport and port storage yards: Prevent ground cracking and extend service life.

Frequently Asked Questions

Q: Will steel plastic composite geogrid rust?

The steel wire is completely sealed with plastic and has passed the 4,000-hour salt spray test (ASTM B117). In actual engineering, no corrosion failure has been observed for 50 years.

Q: Can it replace steel mesh?

Sure! In reinforced soil structures, its tensile strength is equivalent to Φ16@100mm steel mesh, but its weight is only 1/10, and the construction speed is increased by 3 times.

Q: Precautions for winter construction?

When the temperature is less than 5℃ :

Disabled! The brittleness of plastic increases, and it is prone to breakage during laying.

When storing, the rolls should be placed vertically to prevent freezing and sticking between layers.

Purchase suggestions

*Verify the test report of GB/T 21825-2008 (national standard) or ASTM D6637 (American standard);

*The key inspection points are the peel strength of the nodes (which should be greater than the tensile strength of the steel strands) and the carbon black content (≥2% UV resistance).

Ultimate advantage: Increase the bearing capacity of the foundation by 300% at a cost of 10%, making it the king of cost performance for soft soil, steep slopes,and heavy-load projects!

Keywords:

- Material and Structure

*Raw materials

Fiberglass Geogrid: Glass fiber (inorganic material, mainly composed of silicate)

Polyester Geogrid: Polyester fiber (PET, organic polymer)

*Production process

Fiberglass Geogrid: Glass fibers are woven and then impregnated with asphalt or polymer coatings

Polyester Geogrid: High-strength polyester yarns can be warp knitted or welded into grids, and the surface can be covered with polymers

*Physical properties

Fiberglass Geogrid has high rigidity and great brittleness, and is not easy to bend

Polyester Geogrid has good flexibility and strong elasticity, and can adapt to deformation

- Key performance comparison

*Tensile Strength

Fiberglass Geogrid: 30kN/m-300kN/m

Polyester Geogrid: 20kN/m-1000kN/m

*Elongation

Fiberglass Geogrid has an extremely low elongation rate (≤3%), almost no elasticity

Polyester Geogrid is relatively high (13% – 15%), capable of absorbing deformation energy

*High-temperature resistance

Fiberglass Geogrid: excellent (Long-term temperature resistance >200℃)

Polyester Geogrid: average (softening point 230℃, long-term service ≤100℃)

*Acid and alkali resistance

Fiberglass Geogrid: resistant to strong acids and strong alkalis (stable glass composition)

Polyester Geogrid:resistant to weak acids and alkalis,but prone to hydrolysis in strong acid and alkali environments

*Creep resistance

Fiberglass Geogrid: average (prone to brittle fracture under long-term load)

Polyester Geogrid: excellent (strong resistance to long-term deformation)

*UV resistance

Fiberglass Geogrid relies on coating protection (prone to aging after damage)

Polyester Geogrid has excellent performance (with UV absorber added, long service life).

*Low fatigue resistance

Fiberglass Geogrid: low (prone to breakage under repeated loads)

Polyester Geogrid: high (flexible and resistant to dynamic loads)

3. Applicable scenarios

(1)The advantageous scenarios of fiberglass geogrid

*Asphalt pavement crack resistance

It is laid between asphalt layers to suppress reflective cracks by using high modulus (such as adding asphalt to old cement roads).

*High-temperature construction

The performance of hot-mixed asphalt laying is stable at 140-160℃.

*Reinforcement of rigid structures

Airport runways, concrete pavements and other projects that require high-rigidity supports.

(2)The advantageous scenarios of polyester geogrid

*Soft soil foundation reinforcement

Flexible adaptation to foundation deformation and reduction of settlement (for highway/railway subgrades and DAMS).

*Slope and retaining wall

High elongation disperses soil stress and prevents landslides.

*Long-term load-bearing project

It has strong creep resistance and is suitable for structures with high fill soil (such as landfill slopes).

4.Typical engineering cases

After the renovation of the old expressway (Shanghai-Nanjing Expressway), the reflective cracks were reduced by 80% after the asphalt layer was added.

Deep-sea soft foundation treatment (artificial island of Hong Kong-Zhuhai-Macao Bridge), controlling settlement and enhancing the stability of the roadbed.

5.A one-sentence summary

*Fiberglass geogrid: High strength, crack resistance, high temperature resistance, suitable for asphalt pavement and rigid structure.

*Polyester geogrid:Flexible, creep-resistant, corrosion-resistant, suitable for soft foundation reinforcement and long-term engineering.

6.Pitfall Avoidance tips

*Fiberglass geogrid may become brittle due to “alkali precipitation” in a damp and alkaline environment, so an alkali-resistant coating model should be selected.

*Anti-corrosion layers need to be added to polyester geogrid in strong acid (such as pH<3) and strong alkali (such as pH>11) soils.

keywords:

- Key performance comparison

*Manufacturing Process

Non Woven Geotextile:Fibers bonded mechanically (needle-punched), thermally, or chemically.

Woven Geotextile:Fibers woven together (like fabric) on looms.

*Structure

Non Woven Geotextile:Random fiber orientation (felt-like).

Woven Geotextile:Grid-like pattern (warp + weft yarns).

*Primary Function

Non Woven Geotextile:Separation, Filtration, Drainage.

Woven Geotextile:Reinforcement, Stabilization.

*Tensile strength

Non Woven Geotextile:Lower tensile strength, isotropic (similar strength in all directions).

Woven Geotextile:High tensile strength, anisotropic (stronger in machine direction).

*Permeability

Non Woven Geotextile:High (water flows easily through pores).

Woven Geotextile:Low to moderate (dense weave restricts flow).

*Filtration Efficiency

Non Woven Geotextile:Excellent (retains soil while allowing water passage).

Woven Geotextile:Good, but prone to clogging in fine soils.

*Elongation

Non Woven Geotextile:High (stretches more under load).

Woven Geotextile:Low (minimal stretch).

2.Key Properties & Performance

*Hydraulic Behavior (Water Flow):

Non Woven Geotextile: High permeability → Ideal for drainage (e.g., behind retaining walls, under roads).

Woven Geotextile: Lower permeability → Better for erosion control but may require careful soil compatibility.

*Mechanical Strength:

Non Woven Geotextile: Good puncture resistance but lower load capacity → Used for cushioning/protection (e.g., under geomembranes).

Woven Geotextile: High tensile strength → Perfect for soil reinforcement (e.g., steep slopes, embankments).

*Filtration & Soil Retention:

Non Woven Geotextile: Random pores trap soil particles while allowing water → Superior for filtration (e.g., landfill leachate systems).

Woven Geotextile: Uniform pores may clog with fine silts → Requires proper opening size (AOS) selection.

*Durability:

Non Woven Geotetxile are both resist UV/chemical degradation (if made from polypropylene/polyester).

Woven geotextile generally has higher abrasion resistance.

3.Typical Applications

*Road Construction

Non Woven Geotextile : Separation layer between subsoil/aggregate

Woven Geotextile : Base reinforcement for weak subgrades.

*Drainage Systems

Non Woven Geotextile : Wrap for perforated pipes, French drains.

Woven Geotextile : Limited (low permeability).

*Erosion Control

Non Woven Geotextile : Under riprap/armor layers.

Woven Geotextile: Slope stabilization, silt fences.

*Landfills

Non Woven Geotextile: Protection layer for liners, leachate collection.

Woven Geotextile: Reinforcement of cover systems.

*Railway Ballast

Non Woven Geotextile:Separation/filtration beneath tracks.

Woven Geotextile: Trackbed stabilization.

4.How to Choose?

You need drainage, filtration, or separation (e.g., under driveways, behind retaining walls, pond liners).

You need high strength and stabilization (e.g., reinforcing soft soils, building access roads over mud).

*Hybrid Tip: Some projects use both! For example:

Non woven geotextile for drainage + woven geotextile for reinforcement in steep slopes.

5.Quick Reference

Pros Cons

✅ Excellent filtration/drainage ❌ Lower tensile strength

✅ Conforms to uneven surfaces ❌ Prone to creep under sustained load

✅ Cost-effective

Pros Cons

✅ High load capacity ❌ Poor filtration in fine soils

✅ Low elongation ❌ Stiff (harder to install on curves)

✅ Superior abrasion resistance

6.Summary:

Non woven geotextile:Drainage/Filter (water-centric).

Woven geotextile: Reinforcement (strength-centric).