Call us today!

Blog

- Material and Structure

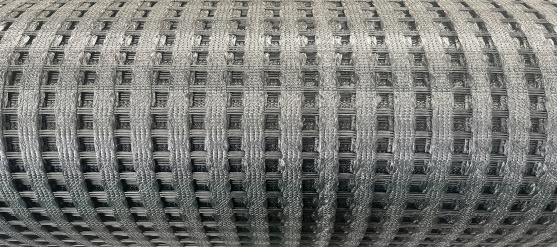

*Raw materials

Fiberglass Geogrid: Glass fiber (inorganic material, mainly composed of silicate)

Polyester Geogrid: Polyester fiber (PET, organic polymer)

*Production process

Fiberglass Geogrid: Glass fibers are woven and then impregnated with asphalt or polymer coatings

Polyester Geogrid: High-strength polyester yarns can be warp knitted or welded into grids, and the surface can be covered with polymers

*Physical properties

Fiberglass Geogrid has high rigidity and great brittleness, and is not easy to bend

Polyester Geogrid has good flexibility and strong elasticity, and can adapt to deformation

- Key performance comparison

*Tensile Strength

Fiberglass Geogrid: 30kN/m-300kN/m

Polyester Geogrid: 20kN/m-1000kN/m

*Elongation

Fiberglass Geogrid has an extremely low elongation rate (≤3%), almost no elasticity

Polyester Geogrid is relatively high (13% – 15%), capable of absorbing deformation energy

*High-temperature resistance

Fiberglass Geogrid: excellent (Long-term temperature resistance >200℃)

Polyester Geogrid: average (softening point 230℃, long-term service ≤100℃)

*Acid and alkali resistance

Fiberglass Geogrid: resistant to strong acids and strong alkalis (stable glass composition)

Polyester Geogrid:resistant to weak acids and alkalis,but prone to hydrolysis in strong acid and alkali environments

*Creep resistance

Fiberglass Geogrid: average (prone to brittle fracture under long-term load)

Polyester Geogrid: excellent (strong resistance to long-term deformation)

*UV resistance

Fiberglass Geogrid relies on coating protection (prone to aging after damage)

Polyester Geogrid has excellent performance (with UV absorber added, long service life).

*Low fatigue resistance

Fiberglass Geogrid: low (prone to breakage under repeated loads)

Polyester Geogrid: high (flexible and resistant to dynamic loads)

3. Applicable scenarios

(1)The advantageous scenarios of fiberglass geogrid

*Asphalt pavement crack resistance

It is laid between asphalt layers to suppress reflective cracks by using high modulus (such as adding asphalt to old cement roads).

*High-temperature construction

The performance of hot-mixed asphalt laying is stable at 140-160℃.

*Reinforcement of rigid structures

Airport runways, concrete pavements and other projects that require high-rigidity supports.

(2)The advantageous scenarios of polyester geogrid

*Soft soil foundation reinforcement

Flexible adaptation to foundation deformation and reduction of settlement (for highway/railway subgrades and DAMS).

*Slope and retaining wall

High elongation disperses soil stress and prevents landslides.

*Long-term load-bearing project

It has strong creep resistance and is suitable for structures with high fill soil (such as landfill slopes).

4.Typical engineering cases

After the renovation of the old expressway (Shanghai-Nanjing Expressway), the reflective cracks were reduced by 80% after the asphalt layer was added.

Deep-sea soft foundation treatment (artificial island of Hong Kong-Zhuhai-Macao Bridge), controlling settlement and enhancing the stability of the roadbed.

5.A one-sentence summary

*Fiberglass geogrid: High strength, crack resistance, high temperature resistance, suitable for asphalt pavement and rigid structure.

*Polyester geogrid:Flexible, creep-resistant, corrosion-resistant, suitable for soft foundation reinforcement and long-term engineering.

6.Pitfall Avoidance tips

*Fiberglass geogrid may become brittle due to “alkali precipitation” in a damp and alkaline environment, so an alkali-resistant coating model should be selected.

*Anti-corrosion layers need to be added to polyester geogrid in strong acid (such as pH<3) and strong alkali (such as pH>11) soils.

keywords:

- Key performance comparison

*Manufacturing Process

Non Woven Geotextile:Fibers bonded mechanically (needle-punched), thermally, or chemically.

Woven Geotextile:Fibers woven together (like fabric) on looms.

*Structure

Non Woven Geotextile:Random fiber orientation (felt-like).

Woven Geotextile:Grid-like pattern (warp + weft yarns).

*Primary Function

Non Woven Geotextile:Separation, Filtration, Drainage.

Woven Geotextile:Reinforcement, Stabilization.

*Tensile strength

Non Woven Geotextile:Lower tensile strength, isotropic (similar strength in all directions).

Woven Geotextile:High tensile strength, anisotropic (stronger in machine direction).

*Permeability

Non Woven Geotextile:High (water flows easily through pores).

Woven Geotextile:Low to moderate (dense weave restricts flow).

*Filtration Efficiency

Non Woven Geotextile:Excellent (retains soil while allowing water passage).

Woven Geotextile:Good, but prone to clogging in fine soils.

*Elongation

Non Woven Geotextile:High (stretches more under load).

Woven Geotextile:Low (minimal stretch).

2.Key Properties & Performance

*Hydraulic Behavior (Water Flow):

Non Woven Geotextile: High permeability → Ideal for drainage (e.g., behind retaining walls, under roads).

Woven Geotextile: Lower permeability → Better for erosion control but may require careful soil compatibility.

*Mechanical Strength:

Non Woven Geotextile: Good puncture resistance but lower load capacity → Used for cushioning/protection (e.g., under geomembranes).

Woven Geotextile: High tensile strength → Perfect for soil reinforcement (e.g., steep slopes, embankments).

*Filtration & Soil Retention:

Non Woven Geotextile: Random pores trap soil particles while allowing water → Superior for filtration (e.g., landfill leachate systems).

Woven Geotextile: Uniform pores may clog with fine silts → Requires proper opening size (AOS) selection.

*Durability:

Non Woven Geotetxile are both resist UV/chemical degradation (if made from polypropylene/polyester).

Woven geotextile generally has higher abrasion resistance.

3.Typical Applications

*Road Construction

Non Woven Geotextile : Separation layer between subsoil/aggregate

Woven Geotextile : Base reinforcement for weak subgrades.

*Drainage Systems

Non Woven Geotextile : Wrap for perforated pipes, French drains.

Woven Geotextile : Limited (low permeability).

*Erosion Control

Non Woven Geotextile : Under riprap/armor layers.

Woven Geotextile: Slope stabilization, silt fences.

*Landfills

Non Woven Geotextile: Protection layer for liners, leachate collection.

Woven Geotextile: Reinforcement of cover systems.

*Railway Ballast

Non Woven Geotextile:Separation/filtration beneath tracks.

Woven Geotextile: Trackbed stabilization.

4.How to Choose?

You need drainage, filtration, or separation (e.g., under driveways, behind retaining walls, pond liners).

You need high strength and stabilization (e.g., reinforcing soft soils, building access roads over mud).

*Hybrid Tip: Some projects use both! For example:

Non woven geotextile for drainage + woven geotextile for reinforcement in steep slopes.

5.Quick Reference

Pros Cons

✅ Excellent filtration/drainage ❌ Lower tensile strength

✅ Conforms to uneven surfaces ❌ Prone to creep under sustained load

✅ Cost-effective

Pros Cons

✅ High load capacity ❌ Poor filtration in fine soils

✅ Low elongation ❌ Stiff (harder to install on curves)

✅ Superior abrasion resistance

6.Summary:

Non woven geotextile:Drainage/Filter (water-centric).

Woven geotextile: Reinforcement (strength-centric).

What’s Asphalt Geogrid ?

Lianyi®Asphalt Geogrid is available in two versions,both for road asphalt reinforcement.First option is fiberglass geogrid and self-adhesive fiberglass geogrid.The second option is a geocomposite made by fiberglass geogrid glued or stitched with PET non woven geotextile or PP non woven geotextile which increase the contact surface original layer. Asphalt geogrid is the best solution to solve asphalt pavement cracking and repair asphalt pavement.

Classification Of Asphlat Geogrid

*Self- Adhesive Fiberglass Geogrid

*Fiberglass Geogrid Composite With Nonwoven Geotextile

*Fiberglass Geogrid Stitched With Nonwoven Geotextile

*Reinforcement of asphalt pavement

Fiberglass Geogrid is used to pave roads considerably reduce the reflective cracking on the course,decrease crack propagation speed,control the formation of ruts and lessen the internal stresses caused by temperature changes.Fiberglass Geogrid for asphalt reinforcement are ideal to improve the performances of roads superstructure,thus allowing them to meet the design requirements.Additionally,these fiberglass geogrid improve loads distribution on the wearing course and thus reduce the settlements.

*Protection from Reflective Cracks

The use of asphalt fiberglass geogrid in asphaltic pavement system mitigates the risk of reflective crack formation.The fiberglass geocomposite reinforcement layer redistributes stresses horizontally in the overall system,thus preventing stress from concentrating and migrating upward to the surface as a crack.

*Prevention of wheel track rutting

The high strength performance of the materials redistributes loads across the entire area of the reinforced road surface.This prevents the formation of wheel ruts,even in high temperature environments.

Benefits Of Asphlat Geogrid

*Safer roads

*Greater roadway service life

*Thinner asphalt layers with no loss of performance

*Reduced costs in construction and long term maintenances

*Stronger base cause

Applications Of Asphlat Geogrid

*Asphalt concrete pavement

*Asphalt layer

*Rehabilitation of old asphalt roads

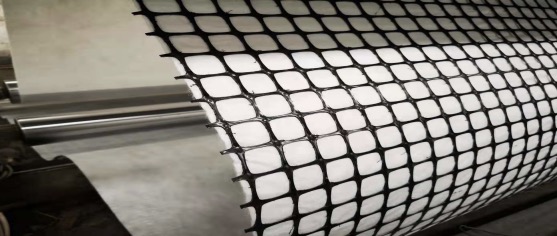

Lianyi®PP geogrid composite is a composite material made by combining PP geogrid (such as Biaxial geogrid made of PP,Fiberglass or Polyester)with non woven geotextile (such as polyester non woven geotextile or pp non woven geotextile through thermal lamination or adhesive bonding processes.It combines the advantages of two materials and is widely used in civil engineering,environmental engineering and other fields.

Classification Of PP Geogrid Composite

*PP Geogrid Composite With Non Woven Geotextile

Features Of PP Geogrid Composite

*High strength and tensile resistance

PP geogrid offers high tensile strength, effectively disperses loads and reduces uneven settlement of the foundation.

*Filtration and drainage

The non woven geotextile layer allows water to pass through while preventing the loss of soil particles, and it also has a drainage function.

*Anti-seepage and isolation

Some composite fabrics can be added with anti-seepage membranes (such as HDPE geomembranes for anti-seepage projects (such as landfill sites).

*Corrosion resistance and durability

Acid and alkali resistant, UV-resistant, suitable for long-term exposure or underground use.

Benefits Of PP Geogrid Composite (

*Distribution of loads and therefore reducing stress concentration over the soil.

*The geogrid’s structural junctions,rigid ribs and thick walls help lock aggregate,increasing its shear resistance. As a result when a vertical load is applied,the aggregate is restrained by the ribs reducing deformation.

*Decrease in long term deformation.

*Increase in load distribution.

Applications Of PP Geogrid Composite

*Highway/railway subgrade

*Enhance the stability of the roadbed and prevent reflective cracks.

*Slope protection

*Fix the soil in combination with vegetation to prevent landslides.

*Landfill

*Anti-seepage composite fabric is used as a cushion layer to prevent the spread of pollution.

*River course improvement

*Protect the bank slope and resist the erosion of water flow.

PP Geogrid Composite Key Points of Construction

*Laying direction: The high-strength direction of the grid must be consistent with the force direction.

*Lap treatment: The transverse lap of the grating should be no less than 10cm, and the longitudinal lap should be no less than 20cm. Geotextile lap joints need to be sewn or bonded.

*Protective layer: Avoid direct exposure to ultraviolet rays and cover the fill soil in time.

Purchase suggestions Of PP Geogrid Composite

*Select parameters such as tensile strength (e.g., above 30kN/m) and permeability coefficient (e.g., ≥0.1cm/s) according to engineering requirements.

*Give priority to well-known brands (such as Lianyi-www.geolianyi.com) to ensure quality.

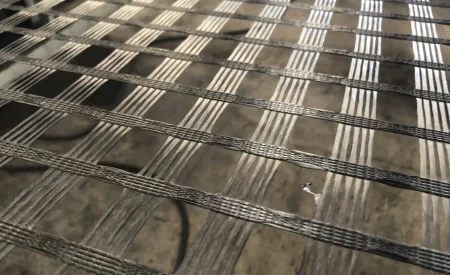

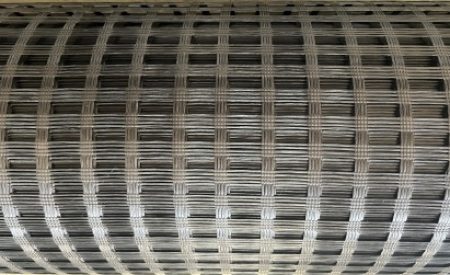

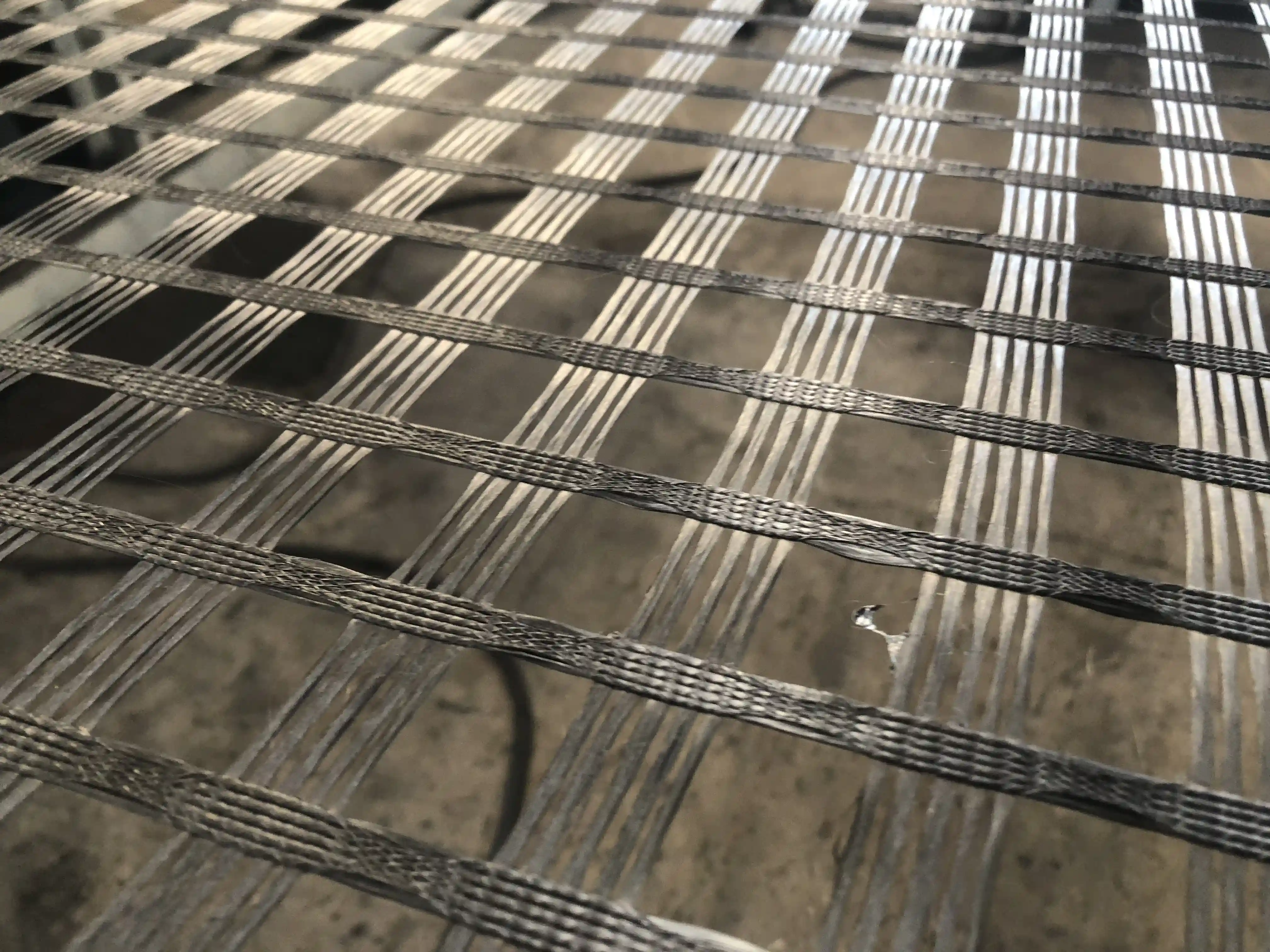

What’s Woven Polyester Geogrid?

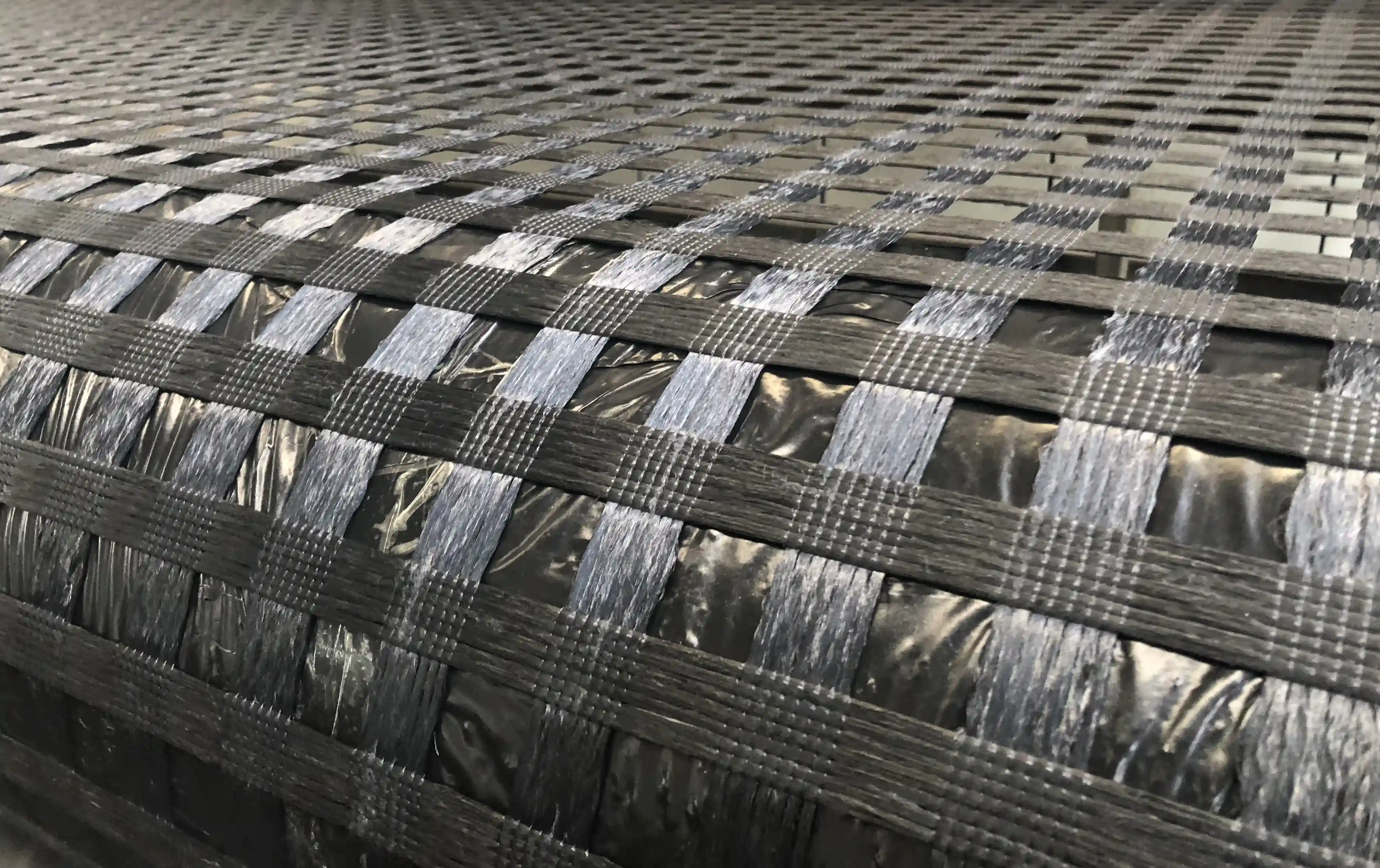

Lianyi®Woven Polyester Geogrid is an engineered woven geogrid that has exceptionally high strength characteristics at low levels of strain.Woven Polyester Geogrid is additionally coated with a polymer that provides high resistance to degradation in soil environments as well as providing additional UV and mechanical damage protection to the fibers.Woven Polyester Geogrid may be constructed with tensile strengths up to 1000 kN/m.Strains generated at ultimate tensile strength are typically less than 12%.Woven Polyester Geogrid has the ability to carry significant loads imposed upon the product from a range of short term as well as very long-term soil reinforcement applications, that has a demonstrated history of performance both here in China and around the world. The product may be manufactured for site specific requirements. The rolls are available in wide widths up to 5.2m to minimise wastage from overlap requirements.

Classification Of Woven Polyester Geogrid

Features Of Woven Polyester Geogrid

*High short-term tensile strength at break: from 20kN/m to 1000kN/m

*Low deformation om short-term break

*Excellent yield performance

*Optimal interaction with all types of soils due to its structure

*Easy and fast installation

*The union between the weft and the warp is perfect,preventing tears

Applications Of Woven Polyester Geogrid

*Steepened reinforced slopes

*Retaining walls

*Veneer reinforcement for landfills

*Soil reinforcement over piled foundations

*Support over voids

*Capping of tailings ponds

*Basal reinforcement of soft soils

*Other applications where soil will benefit from the inclusion of a tensile element for additional load carrying capacity

Keywords:

1. PET Geogrid

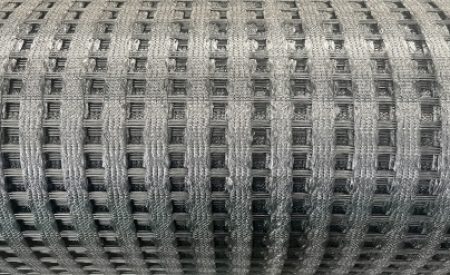

What’s Polyester Geogrid?

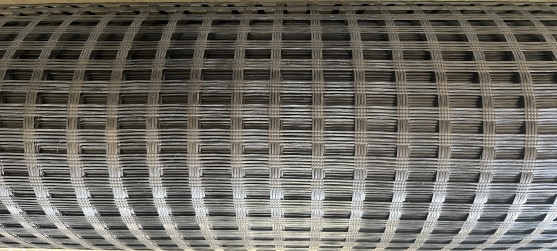

Lianyi®Polyester Geogrid(PET Geogrid) is a geosynthetic material mainly made of polyester (polyester fiber) yarns with PVC coating,which is widely used in the fields of reinforcement, strengthening and protection in civil engineering.

Classification Of Polyester Geogrid

Features Of Polyester Geogrid

*High strength: Polyester fibers have a relatively high tensile strength, which can effectively disperse loads and enhance the stability of soil.

*Corrosion resistance: Resistant to acids, alkalis and chemical corrosion, suitable for complex geological environments.

*Creep resistance: Small deformation under long-term loading, and its stability is superior to that of ordinary plastic grating.

*Good flexibility: Adapt to foundation deformation and reduce the risk of cracking.

*Light weight: Convenient for construction, low transportation and laying costs.

Applications Of Polyester Geogrid

*Highway/railway subgrade: Distribute loads to prevent uneven settlement.

*Slope reinforcement: It combines with soil to form a stable structure and prevent landslides.

*Retaining wall: As a reinforcing material, it enhances the shear strength of the wall.

*Soft soil foundation treatment: Reduce settlement and enhance bearing capacity.

*Landfill site: Used for base reinforcement and anti-seepage system protection.

Production process Of Polyester Geogrid

*Raw material: High-strength polyester filament (PET) yarns.

*Process: It is woven into a mesh structure by a warp knitting machine and then treated with a coating (such as PVC or asphalt) to enhance durability.

*Type: It is divided into unidirectional (unidirectional force) and bidirectional (bidirectional force) grating.

Polyester Geogrid Key Points of Construction

*Laying preparation: Clean the base layer to ensure it is flat and free of sharp objects.

*Laying direction: Determine the unidirectional or bidirectional force direction according to the design.

*Lap length: Usually 10-15cm, it needs to be fixed with special connectors.

*Filling material selection: Coarse-grained soil is preferred and compacted in layers (each layer thickness ≤30cm).

*Avoid long-term exposure to ultraviolet rays: Cover and fill soil in a timely manner after construction.

Precautions Of Polyester Geogrid

*Storage: Avoid direct sunlight to prevent aging.

*Construction temperature: Polyester may become brittle at low temperatures, so construction should be avoided in extremely cold environments.

*Design basis: The strength, width and node strength should be selected according to the engineering requirements.

Keywords:

1. PET Geogrid